Capturing high-quality photographs of aluminum might be fairly difficult because of varied components. Nonetheless, on this video, we get a particular glimpse into the Fronius CMT welding course of, showcasing the intricate particulars of this system captured utilizing a thermal digicam.

Imaging aluminum welding is especially robust as a result of the steel is so extremely reflective, has a considerably decrease melting level than different metals, sometimes round 660°C, and dissipates warmth in a short time as soon as welded. Consequently, it may be very robust to get good photographs of aluminum welding processes.

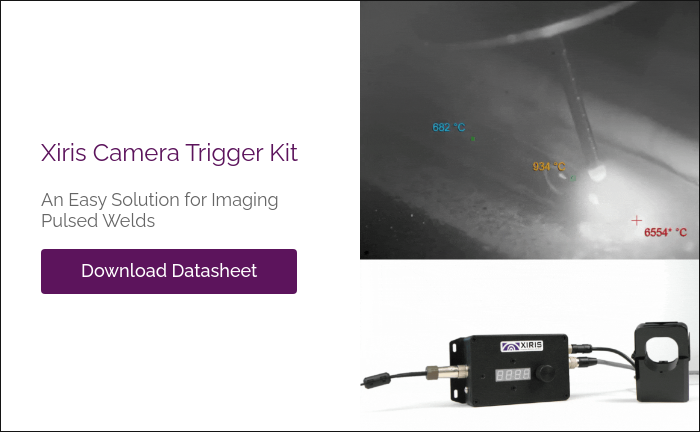

To perform this feat, a Xiris XIR1800 digicam particularly calibrated for aluminum was used to amass thermal photographs of the welding course of. The digicam was outfitted with a filter exactly calibrated to measure temperatures as much as 1000°C and work with a really quick publicity time of about 0.5 ms, which is ten occasions sooner than the usual publicity time of 5 ms.

To make sure that one of the best, most secure photographs of the GMAW welding course of have been captured, a Xiris Voltage Set off Equipment was used to synchronize the picture acquisition to the waveform of the welding energy provide.

This enabled precision timing for capturing the portion of the steel switch that was of biggest curiosity to the viewer. The video above begins with picture seize working with no set off. The ensuing picture is variable, with a lot of variation in brightness because of the GMAW expulsion.

About 8 seconds into the video, the voltage set off was turned on and set to set off at a selected level within the energy waveform to permit the digicam to picture the “No Arc” situation.

This allowed picture acquisition to happen when no arc was current, offering an correct illustration of the welding course of. The distinction in picture high quality is dramatic, highlighting how efficient the set off sign is in making a secure video from the thermal digicam.

Within the above video, the wire used within the course of was 1.2mm in diameter and the welding pace was about 5 meters (200”) per minute on a flat aluminum plate.

When analyzing the ensuing movies, a number of important parts change into obvious as soon as the triggering takes impact.

Firstly, the wire itself is clearly seen, together with its heated molten tip as a result of there isn’t any flashing arc.

Moreover, there’s a distinct define of the soften pool, showcasing the exact boundaries of the liquefied aluminum.

The picture additionally reveals the extent of the mushy zone, the place the soften pool transitions right into a semi-solid state.

The cooling bead can be clearly depicted, representing the solidification of the molten aluminum.

Lastly, the picture supplies a transparent view of the bottom materials and the efficient cleansing zone of aluminum oxide previous to welding, emphasizing the meticulous preparation required for profitable aluminum welding.

By utilizing the superior expertise of the XIR1800 thermal digicam mixed with a Voltage Set off to amass exactly timed movies, the above video supplies a transparent perception into the complicated world of aluminum welding and all its parameters.

It showcases the outstanding capabilities of the XIR1800 thermal digicam when used with the modern Voltage Set off Equipment to create synchronized video.

Conclusion

The above video not solely highlights the intricate particulars of the Fronius CMT welding course of in motion on aluminum, but in addition emphasizes the significance of utilizing a exact picture set off with a thermal digicam to seize the absolute best photographs of aluminum welding.