Xiris Weld Cameras are sometimes used to allow operators to view the welding course of remotely and monitor welding processes, enhancing operator security and effectivity. With the necessity for larger ranges of effectivity and automation, including weld cameras that can be utilized to measure and monitor welding options is turning into ever extra necessary.

The XVC-750 weld digital camera combines 140+dB of Excessive Dynamic Vary (HDR) functionality with Close to Infrared (NIR) sensitivity to offer excessive distinction pictures in and across the soften pool.

NIR sensitivity enhances the picture distinction within the picture by including a element of the warmth current in a weld setting to the seen gentle current.

(Maintain on! Maintain scrolling to take a look at the pictures!)

The result’s the next distinction picture particularly for options with excessive warmth emission such because the soften pool and weld bead but additionally for different options within the neighborhood of the weld that mirror the warmth such because the mum or dad materials, weld seam of added welding wired.

The improved distinction generates a picture the place the options of an open arc weld course of may be extra clearly seen and detected by human operators or machine imaginative and prescient processes alike.

See Fig 1 under for a picture instance of a weld course of taken by an XVC-750 digital camera.

%20Screenshot.jpg?width=990&height=506&name=Figure%201%20GMAW%20-Fillet%20Weld%20with%20XVC750%20on%20the%20trailing%20edge%20(No%20Illumination)%20Screenshot.jpg)

Determine 1 – GMAW -Fillet Weld with XVC750 on the trailing edge (No Added Illumination)

A few of the Key Advantages of the XVC-750 digital camera system are:

- Wonderful excessive distinction pictures for Machine imaginative and prescient duties, significantly for monitoring the soften pool and cooling bead;

- A transparent view of all of the necessary options in and across the soften pool and welding course of.

- Excessive-resolution imaging to detect attainable defects within the soften pool and cooling bead.

- Primarily based on the identical versatile compact digital camera platform as different XVC700 cameras that permit for the optics to be mounted at varied angles to the primary digital camera physique.

The higher distinction XVC-750 pictures that permit for higher course of monitoring by the operators are additionally higher for automated Machine Imaginative and prescient duties. When coupled with Xiris’ WeldStudio Professional software program, machine imaginative and prescient evaluation is rather more strong due to the development in distinction of the NIR pictures.

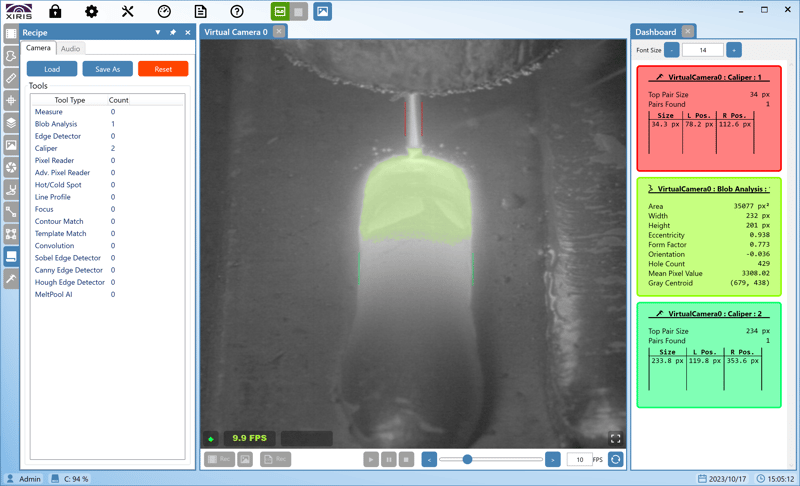

Determine 2 – GMAW -Bead Trailing view with XVC750 in WeldStudio Professional

Determine 2 – GMAW -Bead Trailing view with XVC750 in WeldStudio Professional

Determine 2 reveals Machine imaginative and prescient instruments in WeldStudio Professional with measurements for wire location and weld bead width measurement occurring in actual time utilizing the caliper instrument. Additionally within the above picture, the MeltPool-AI instrument is proven highlighting the soften pool and performing exact soften pool form and measurement measurements, together with:

|

Space |

Gap Rely |

| Width |

Perimeter |

| Peak | Euler Quantity |

| Eccentricity | Imply Pixel Values |

| Type Issue | Centroid |

| Orientation |

And lots of others. These measurements can then be used for automated course of monitoring and attainable course of changes.

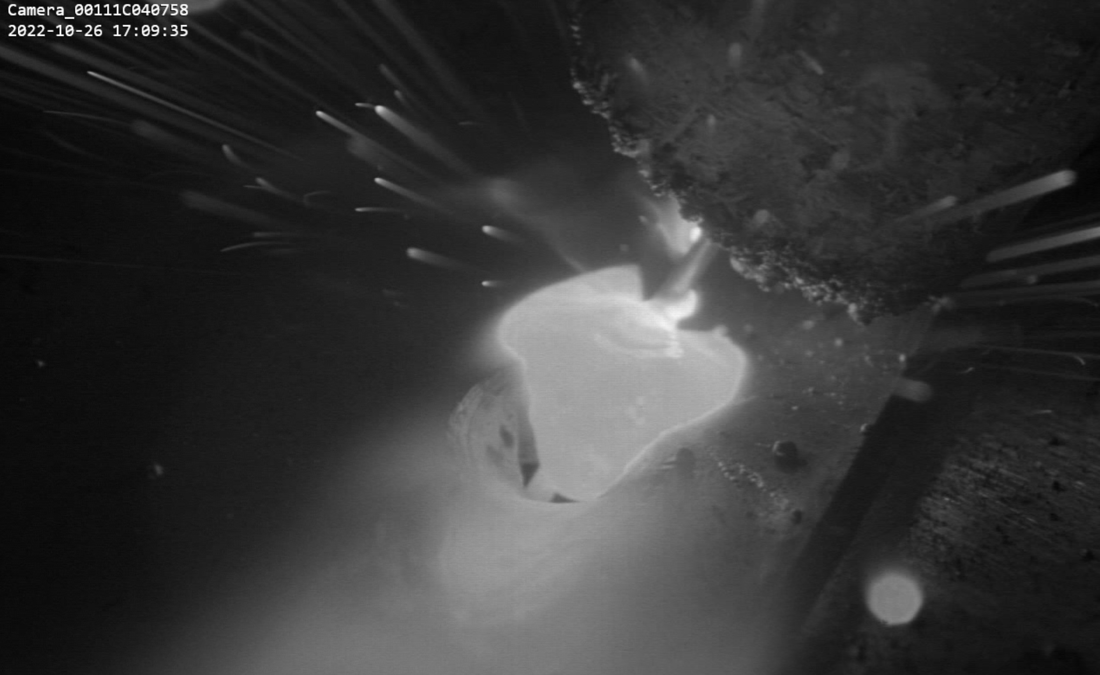

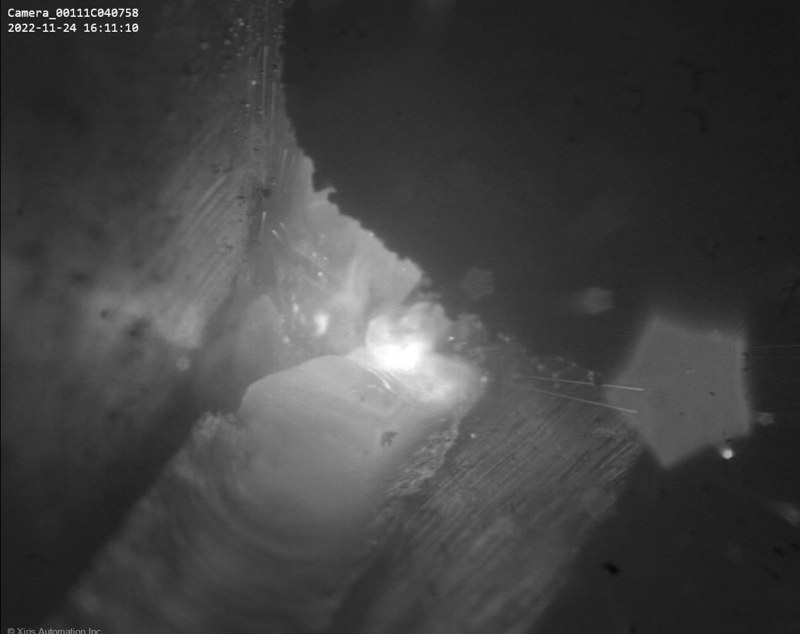

The improved pictures supplied by the XVC-750 helps within the detection of discontinuities and attainable defects which might be troublesome to detect in any other case, together with wire feeding points, burn-through, contamination, porosity and lack of fusion or off-seam.

The detection of those may be particularly efficient when utilizing Synthetic intelligence (AI) or Machine Studying (ML) defect detection strategies.

Determine 3 – GMAW -Lap Joint Burn by Determine 3 – GMAW -Lap Joint Burn by |

Determine 4 – GMAW -Fillet Joint Lack of Fusion |

The NIR functionality of the XVC-750 enhances picture distinction usually of weld processes. For some purposes nevertheless, it could be useful so as to add further illumination to see extra of the background across the weld, akin to the bottom materials, extra clearly.

That is very true if the weld arc and bead is small relative to your complete Discipline of View (FOV) when the digital camera is utilized in trailing view purposes; or when attempting to see the seam extra clearly and its alignment to the torch for main view purposes.

See Determine 5 for an instance of a number one view utility.

Determine 5 – GTAW Main facet with Illumination

Due to its compact measurement and the number of optics angles through which it may be configured, the XVC 750 weld digital camera is right for automated, and robotic welding programs. However The XVC7x0 collection :

The Numerous Configurations of the XVC-7×0 Weld Digicam

In abstract, the XVC-750 weld digital camera is a superb digital camera selection for many manufacturing welding purposes. It may be used to enhance the distinction of sure open arc welding processes for operator monitoring, permitting the operator to view the method remotely.

Additionally, as a result of it generates larger distinction, secure picture, the XVC-750 digital camera can be utilized in purposes the place machine imaginative and prescient evaluation is required to extract measurements of assorted options of the weld, making it appropriate for integration into all forms of automated welding programs.