Metal is a structural materials broadly utilized in quite a few industries and functions. The properties of various steels differ from arduous and brittle to ductile and robust, from simply rusting to proof against corrosion in excessive environments.

To meet the necessities of assorted functions, quite a few metal grades have been developed to supply a sure energy, ductility, hardness, toughness, or corrosion resistance.

Such a variety of properties is feasible as a result of not like another metals, metal has not one stable state however a number of solid-state phases. These phases could have completely different atom distributions on crystal lattice, completely different ranges of dislocation and the deformations of crystal construction, and, consequently, completely different mechanical properties.

The transformations from one section to a different happens in the course of the heating and cooling processes at sure temperatures under the melting level. Welding is an instance of such a heating-cooling cycle.

At a given level, the temperature of the weldment rises quickly in the course of the weld arc passage after which cooling takes place as soon as the arc passes. The cooling section is often for much longer than the heating section.

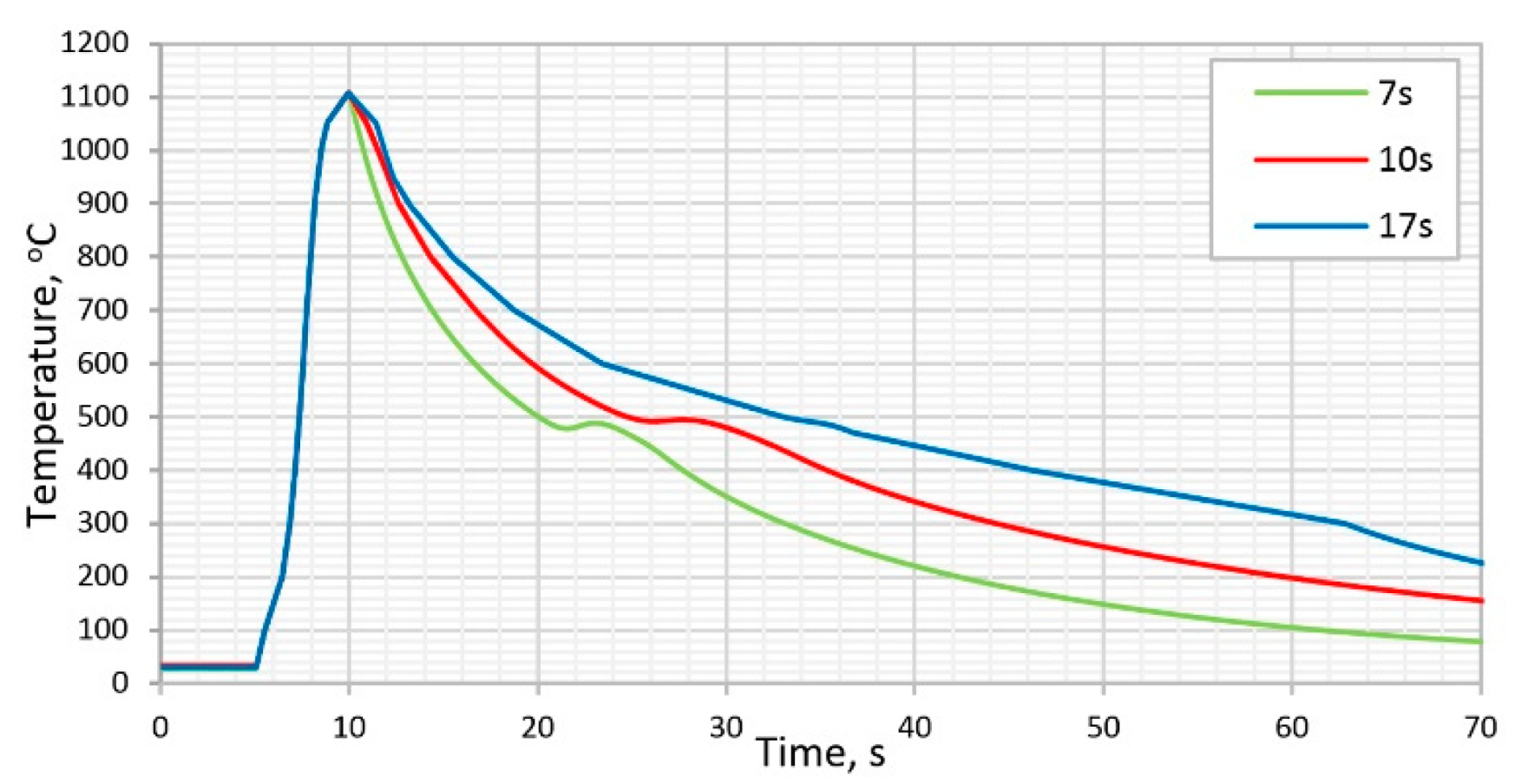

The cooling charge is among the key elements that determines the results of such transformations in a weld. The toughness and hardness of the weld will depend upon how briskly it cools down publish welding. To quantify the cooling charge, the reciprocal of the speed is commonly used, i.e., the time it takes to chill between two temperatures. The cooling time between 800 ˚ C and 500 ˚ C is probably the most broadly used measure, known as t8/5.

|

|

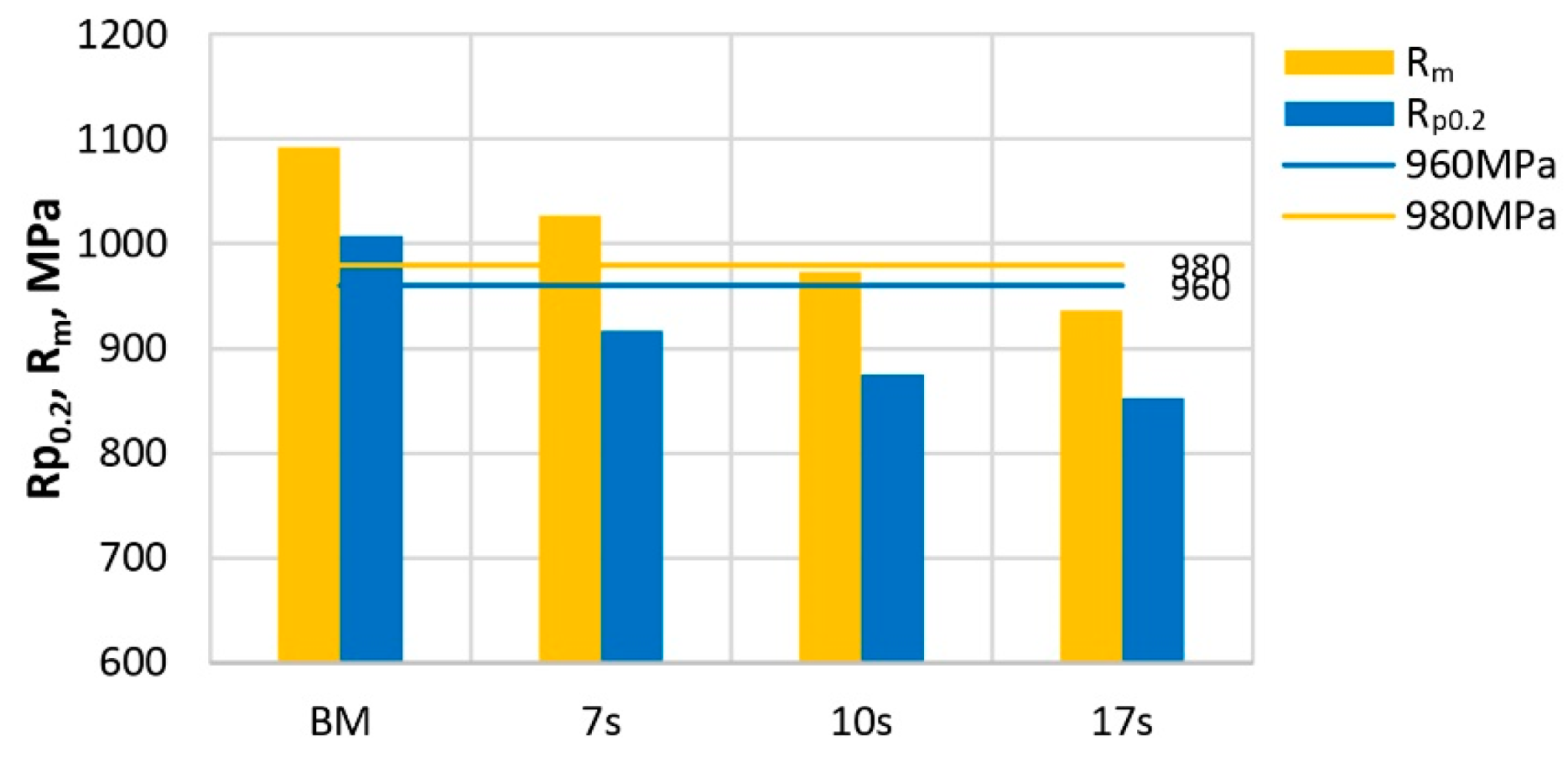

The impact of the t8/5 cooling time on S960 high-strength low-alloy metal (proper) and the examined thermal cycles (left) as reported by [1]. Longer cooling time led to a discount within the yield and tensile energy.

Relying on the metal grade, particular necessities on the cooling charge could apply. The necessities are intently linked to the time period weldability.

Weldability refers to how “straightforward” it’s to weld a sure grade.

For instance, if an alloy is taken into account low and even non-weldable, it signifies that the allowed vary of welding parameters may be very slender. These parameters embody journey pace, warmth enter, arc voltage and present, preheat, and cooling charge. Any variations of the parameters past the desired limits will result in the next defect chance.

For that reason, managed cooling charges are required in welding of many alloys. Too-fast cooling could end in arduous and brittle microstructural phases that cut back ductility.

Quick cooling charges additionally enhance the quantity of hydrogen trapped contained in the weld metallic which will result in cracks at room temperature hours after the welding is completed.

Hydrogen-induced cracking, or chilly cracking, is a major defect in lots of metal functions, similar to pipelines, structural members, and so on. Slower cooling will increase the chance of hydrogen diffusing out of the weld, lowering the chance of chilly cracking.

Too sluggish cooling, nevertheless, could cut back the yield and tensile energy of the bottom metallic (Determine 1). It’s significantly related to high-strength low-alloy (HSLA) steels.

One other issue to think about is the height temperature {that a} explicit level reaches in the course of the weld cycle. In case of the weld bead, the melting temperature might be thought-about as the height temperature.

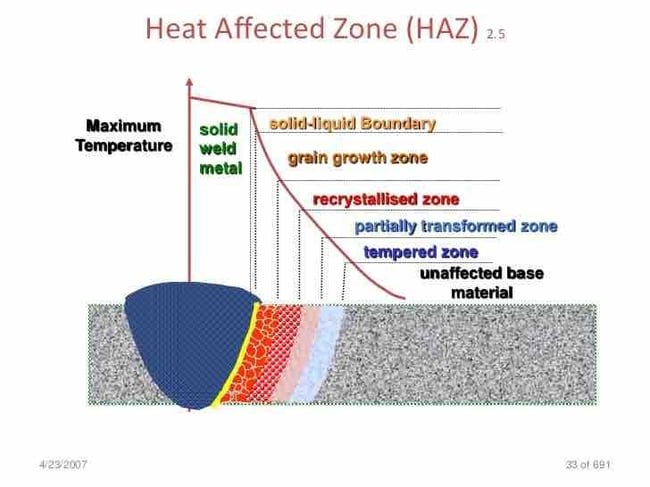

For the bottom metallic adjoining to the weld, the height temperature will differ relying on the gap it’s away from the melting line. The areas close to the weld bead, the place the preliminary base metallic microstructure reworked throughout welding, is named the Warmth-affected zone (HAZ) (see Determine 2).

The impact of the height temperature on the bottom metallic adjoining to the weld. The areas of the heat-affected zone (HAZ) remodel in a different way relying on the utmost temperature reached throughout welding. Reprinted from [2]. |

Cooling charge and peak temperature are often estimated by welding engineers as a operate of welding parameters utilizing formulae derived from a degree warmth supply mannequin relationship again to the Forties.

(Obtain A Information for Utilizing Thermal Cameras in Welding and Metallic AM R&D – Whitepaper)

These formulae could also be an oversimplification in case of a extra advanced geometry than a flat plate. Additionally they require the thermal conductivity of the alloy used within the software. A desk conductivity worth for iron for instance, could differ from the precise conductivity and should introduce an additional error within the cooling charge.

Another could be a thermal welding digicam. Actual-time floor temperature monitoring supplies considerably extra management over the cooling charge and the height temperature at each level of the joint whatever the workpiece geometry.

A thermal digicam such because the Xiris XIR-1800 digicam supplies correct temperature measurements of the weld arc within the video body throughout a variety of temperatures – from above melting level right down to round 300 C relying on the optics chosen.

Such a spread permits course of builders to watch each solidification and the temperature dynamics between 800 ˚C and 500 ˚C in a single body. Such a device can present an unprecedented management in your WAAM design or welding process for an “unweldable” alloy.

References:

[1] Mičian, Miloš, et al. “Impact of the t 8/5 Cooling Time on the Properties of S960MC Metal within the HAZ of Welded Joints Evaluated by Thermal Bodily Simulation. Metals 10.2 (2020): 229.

[2] http://arcraftplasma.blogspot.com/2016/09/method-of-calculating-cooling-rate-in.html

To be taught extra about how one can implement Xiris Thermal Digicam, attain out to our product specialists.

Keep updated by following us on social media or subscribe to our weblog!