Slender hole welding is a becoming a member of course of that’s most frequently used to weld thick sections of fabric economically. It requires preparation of the joint with steep angles designed to require much less weld steel and fewer welding time to fill the joint which is normally not more than about 25 mm (1”) in width.

Tungsten Inert Fuel Welding (TIG or GTAW) is commonly used because the welding methodology of alternative for a lot of slim hole welding purposes corresponding to pipe welding, stress vessel building and different crucial fabrications and is commonly built-in into weld automation gear corresponding to in orbital welding or linear tractor welding techniques.

Due to the depth of the hole (which may be as much as 300 mm), it’s important to have the ability to monitor the progress of the weld to confirm the integrity of the weld course of. Some defects, corresponding to lack of sidewall fusion, are a typical drawback in slim hole welding, requiring a continuing, good high quality view of the welding course of to correctly monitor it.

Why Add a Digital camera to the Slender Hole Welding Course of?

-

Search for sidewall fusion – usually brought on by incorrect welding parameter settings or poor floor preparation, it is a random occasion that wants fixed monitoring to be seen.

-

Search for Interpass fusion – when one cross is deposited on high of a earlier cross, incorrect welding parameters or cleanliness points may trigger fusion points between passes, and different random occasions that requires fixed monitoring.

-

Guarantee alignment of arc to sidewall – Even one of the best gear can wander over time, inflicting higher protection and fusion on one aspect of the weld than the opposite.

-

Guarantee any machine oscillation of the weld torch is symmetric – Oscillation is an effective way to enhance the sidewall fusion on either side of the weld, however it must be continuously monitored to make sure that either side are getting enough dwell time for fusion to happen.

Weld cameras have been used to assist monitor slim hole welding processes for a few years. Due to the small measurement of the slim hole channel, cameras should compete for restricted area with all the standard gear within the space of the weld: one or two weld torches, wire feeders and even pre-heaters.

The presence of all this gear requires that any digicam added to the combo should be very small.

Traditionally this was addressed utilizing a class of cameras often known as “lipstick” or “bullet” cameras – small cameras of about 17 mm in diameter, usually color, that had been sufficiently small to see down into the hole of the slim groove seam.

The early cameras had been all analog and didn’t supply HDR (Excessive Dynamic Vary) imaging which meant that the welding arc was usually saturated. As a result of there was nothing higher, this normally met the trade’s wants till the cameras had been now not being manufactured. Lately, many fabricators have struggled to run their slim hole welding gear as their legacy lipstick weld cameras have been slowly dying with no appropriate alternative in the marketplace.

Recognizing this concern, Xiris developed the XVC310 lipstick digicam. With a few years’ expertise growing Excessive Dynamic Vary (HDR) cameras appropriate for welding, Xiris labored to develop a small format all-digital coloration digicam that may function a drop-in alternative for legacy slim hole welding cameras.

Fig 2: The Xiris XVC310 Lipstick HDR Weld Digital camera (Xiris) |

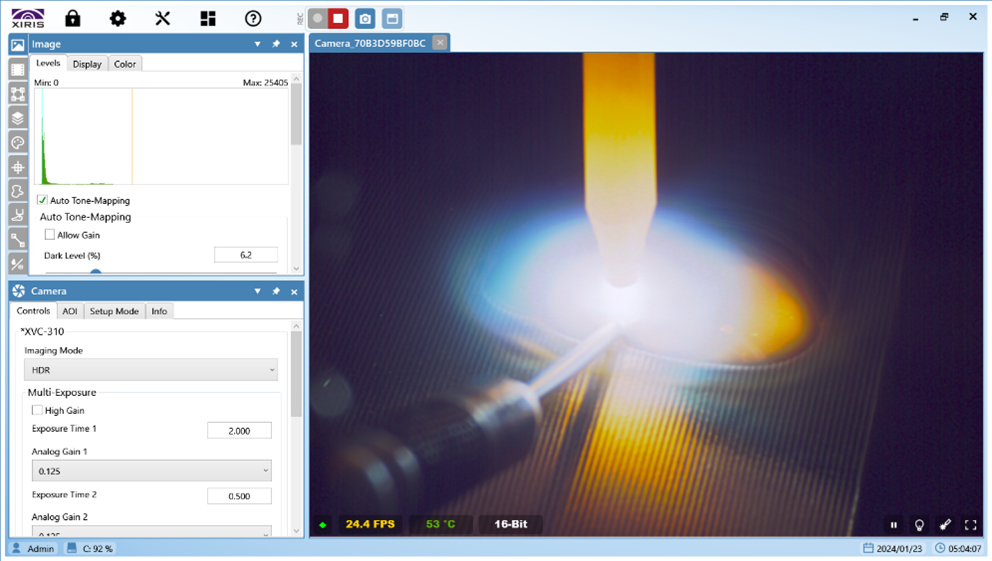

The XVC310 has HDR imaging functionality that generates excessive distinction pictures (>120 dB) of the welding course of to permit operators to remotely view and monitor welding processes the place entry to the joint is restricted. The HDR imaging functionality permits for the show of the weld arc and its darker surrounding atmosphere all in the identical picture.

The digital video info that’s generated may be despatched to a PC for show, recording and playback. Partnered with Xiris’ machine imaginative and prescient software program, options such because the TIG tip, soften pool, weld bead, weld seam, guardian materials and wire feeding may be mechanically inspected earlier than, throughout and after welding.

The XVC310 represents the following era of digicam for Slender Hole Welding Processes with just a few key benefits:

- Compact Design: At 17 mm diameter, the Digital camera Head mirrors the scale of most legacy Lipstick cameras, guaranteeing seamless integration into tight areas.

- HDR enhanced Coloration Imaging: With greater than 120 dB of HDR functionality, the XVC-310 delivers excellent pictures, offering a transparent and detailed view of crucial options inside and across the soften pool and welding course of. The colour and look of these characteristic can present invaluable details about the welding course of and base materials.

- Trade 4.0 Connectivity: The system is definitely related by way of a Digital camera Controller to Xiris Software program via GigE ethernet, with the flexibility to construct next-level automation by way of machine imaginative and prescient performance in Xiris’ WeldStudio Professional software program suite.

Fig. 3: Photographs from the XVC310 Weld Digital camera in WeldStudio Professional |

The place to Put a Weld Digital camera in a Slender Hole Welding Course of?

There are actually two decisions as to the place a digicam needs to be positioned to observe a Slender Hole welding course of: in entrance of the torch wanting again on the course of (Main View) and behind the torch wanting ahead to the method (Trailing View). Each views can present different types of knowledge:

Main View – offers a very good picture of the forefront of the soften pool, the seam-to-torch alignment, the situation of the torch tip and the standard of the sidewall or interpass fusion.

Trailing View – offers a very good picture of the form and site of the solidifying weld bead, the wire feed velocity, wire tip location and droplet formation, floor defects corresponding to slag, porosity or silicates.

Fig. 4: The Slender Hole Welding Course of with Flanges to mount Digital camera for Main or Trailing Views |

Abstract

Slender Hole Welding is a crucial course of to manage correctly to make sure crucial welds are made accurately. For this to occur, cameras to observe the method are an integral part of any slim hole welding system. Legacy cameras which have been used through the years are now not accessible or out of date.

The brand new XVC310 lipstick weld digicam from Xiris is a drop-in alternative for a lot of the legacy cameras because of its compact measurement and offers the following era of functionality as an all digital digicam that may ship pictures for weld monitoring and inspection.

Keep updated by following us on social media or subscribe to our weblog!