Selecting a thermal digicam to your particular course of in at the moment’s market will be fairly a problem as a result of big range obtainable. On this weblog, we are going to focus on the varied features of thermal cameras and their efficiency in sizzling metallic processing purposes, akin to welding and wire-based metallic AM. Particularly, we are going to evaluate near-infrared (NIR) and short-wave infrared (SWIR) thermal cameras when monitoring or measuring the temperature of welding processes.

Each NIR and SWIR cameras have gained reputation in varied industrial purposes, efficiently competing with conventional Mid-Wave (MWIR) and Lengthy-Wave Infrared (LWIR) cameras. That is attributed to their vast temperature vary, excessive accuracy, and infrequently, decrease price.

An extra good thing about NIR and SWIR cameras is the decrease measurement error on account of incorrect emissivity settings. For any sort of infrared temperature measurements, it’s crucial to know the emissivity of the floor of a sizzling metallic whose temperature is to be measured.

Nonetheless, the worth of the emissivity might differ relying on the situation of the floor (texture, floor oxidation, and so forth.) and its temperature. Measurements by NIR and SWIR thermal cameras are as much as 10 occasions much less affected by an incorrect emissivity worth than MWIR and LWIR cameras. Because of this, they’ll make correct non-contact temperature measurements appropriate for metallic processing purposes in harsh environments.

|

|

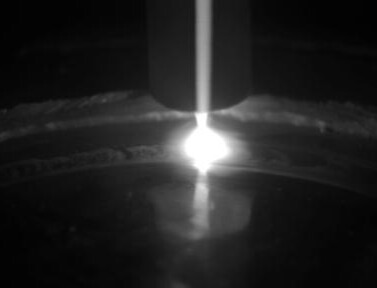

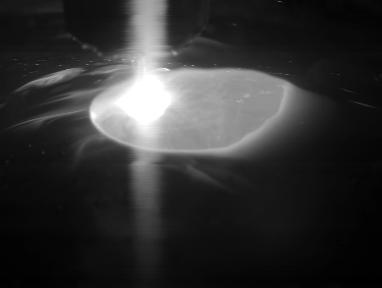

Determine 1. GTAW of delicate metal. The NIR thermal digicam (left) vs SWIR thermal digicam (proper). Notice (a) how clear the arc is, within the SWIR vary; (b) brighter ceramic shielding fuel cup (higher sensitivity at decrease temperatures) in SWIR; (c) saturation from the arc within the NIR picture and a few blooming current.

NIR and SWIR thermal cameras function in intently spaced wavelength ranges in comparison with MWIR and LWIR cameras. NIR cameras usually function round 800 to 1000 nm, whereas SWIR cameras vary from 900 to 1700 nm, primarily decided by the properties of their sensors – InGaAs sensors for SWIR cameras and CMOS sensors for NIR thermal cameras.

Each NIR and SWIR cameras have discovered purposes in weld course of monitoring. The Xiris’ XIR-1800 thermal digicam is a SWIR digicam that has been extensively utilized by OEMs, researchers, and finish customers in varied metallic working purposes from the welding of metal tubes to Wire Arc Additive Manufacturing (WAAM).

NIR thermal cameras are recognized for his or her success in particular metalworking processes like metallic casting, however can they be used as effectively in welding and WAAM? Let’s have a better look.

Relying on the SWIR or NIR wavelength vary used within the digicam, there’s a distinction in:

- How a lot gentle is emitted by heated objects (weld bead); and

- How a lot gentle is emitted by the welding arc (for arc-based processes).

The primary vital distinction between the 2 digicam applied sciences is the minimal measured temperature.

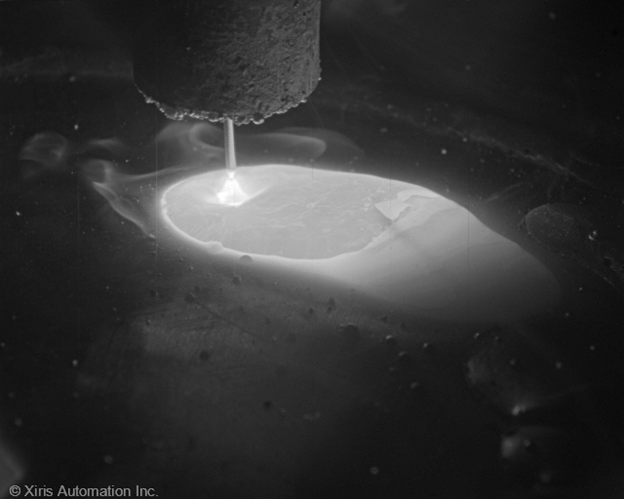

Heated objects emit gentle in accordance with Planck’s legislation, and on the melting factors of steels, titanium, or nickel alloys, there’s a comparable quantity of sunshine emitted within the NIR and SWIR spectrum ranges. Nonetheless, because the temperature goes down, there’s a rising distinction between the 2 spectral ranges. With a SWIR digicam it isn’t an issue to measure all the way down to 350 °C and even attainable in some circumstances to go as little as 250 °C. Whereas with a NIR digicam, 450 °C is typical of the bottom temperature that may be reliably measured with no compromise within the picture decision.

|

|

|

Determine 2. GMAW in Quick Circuit mode. Thermal photos from the NIR thermal digicam (left) and the SWIR welding thermal digicam (proper). The photographs had been taken nearly concurrently. Notice the novel distinction within the decrease temperature sensitivity ultimately of the weld bead. The thermal knowledge disappears after one weld pool size within the NIR picture whereas your complete weld is properly seen within the SWIR thermal body.

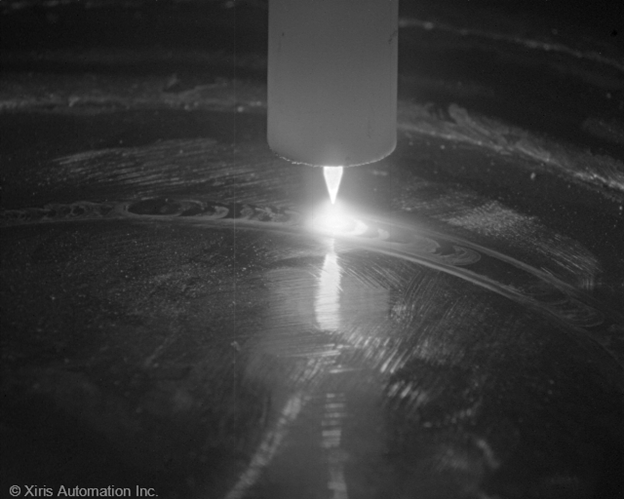

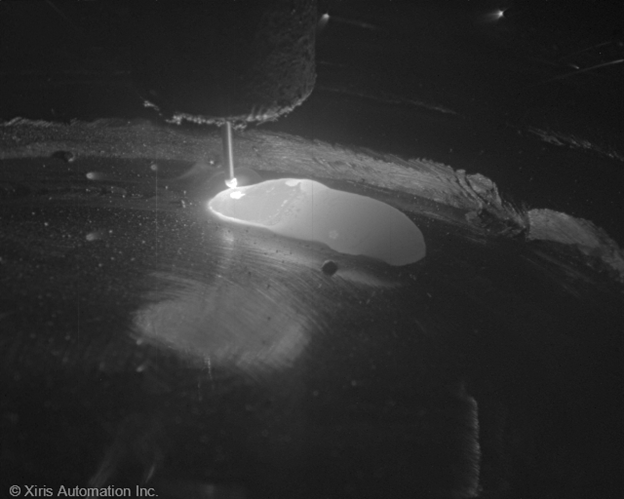

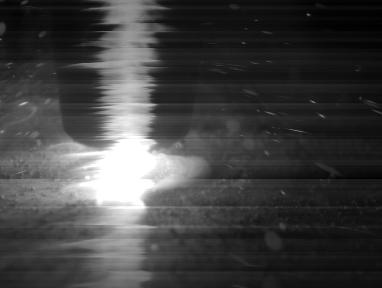

The opposite essential characteristic to contemplate is the presence of the arc. The welding arc is a strong gentle supply that will saturate the picture, even with a high-dynamic vary (HDR) sensor. Making certain that each the good and hottest elements of the world of curiosity match inside the digicam’s temperature measurement vary whereas avoiding saturation by the arc is a non-trivial job, as seen within the Figures beneath.

The photographs from the NIR digicam had been saturated by the arc normally with the dimensions of the saturated space various for various processes. A SWIR digicam can take care of the arc significantly better: there’s usually little or no saturation as can seen within the photos beneath. As well as, decrease minimal temperatures will be measured by SWIR cameras than obtainable from NIR cameras.

|

|

Determine 3. GMAW in Spray metallic switch mode. The NIR (left) and SWIR (proper) thermal photos. Notice the saturation and the darkish weld pool environment within the NIR picture, however nonetheless good distinction between the soften pool and its surrounding weld bead. Within the SWIR picture the weld pool, the arc, and the cooling weld bead are clearly seen/measurable.

One other distinctive characteristic of SWIR is its skill to see via fumes and smoke, as illustrated in Determine 4. It additionally typically applies to the arc itself: with SWIR imaging, the arc is extra clear, and infrequently it’s attainable to see although the arc sooner or later on this wavelength vary (see Determine 1).

SWIR imaging generates a transparent picture the place all the mandatory options are seen, akin to each the main and trailing edges of the weld pool, the situation and state of the filler wire (together with the droplet formation), and the situation of the weld pool relative to the seam. These options won’t be seen in NIR, because the arc is brighter and never clear at these wavelengths.

|

|

Determine 4. FCAW-S (flux-cored self-shielded). The NIR (left) and SWIR (proper) thermal photos. Notice the saturation within the NIR picture, taken with a Rolling shutter. Within the SWIR picture taken with a World Shutter, the weld pool and the cooling weld bead are clearly seen/measurable. The arc is just about clear.

Conclusions

Each NIR and SWIR thermal cameras are an excellent different to conventional MWIR and LWIR thermal cameras – they’ll measure a variety of temperatures at excessive accuracy. However there are variations between the 2 digicam applied sciences.

In welding and WAAM purposes, it is very important match your course of with the fitting thermal digicam. If any temperature measurements are wanted for options which are beneath ~500 °C, then SWIR thermal cameras such because the Xiris XIR-1800 are the higher alternative to your course of. In case you are making an attempt to keep away from saturation of the arc within the picture, or fumes and spatter are a problem in your course of, then a SWIR thermal digicam could be a better option for you, too. Nonetheless, in sure conditions, NIR cameras such because the Xiris XVC750 can obtain primary imaging utilizing thermal knowledge for enhanced distinction.