Wire-arc additive manufacturing (WAAM) is a fabric deposition course of that builds up a construction layer-by-layer utilizing a multi-axis movement management system and a wire arc welding course of. The thermal stability of the method is usually a problem: the interlayer dwell time in WAAM is usually preset earlier than the build-up commences. In consequence, the required cooling time is often calculated empirically; it often doesn’t account for the warmth collected within the deposit from one layer to the following.

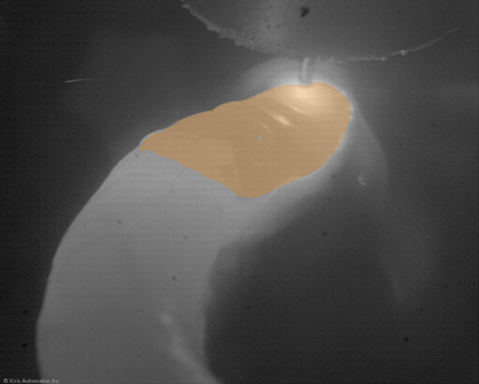

Determine 1. WAAM High quality Monitoring with the MeltPool AI picture evaluation device. The proper soften pool geometry (a) results in a smoother, extra even floor (b) whereas an overheated deposit may cause an uncontrolled soften pool progress till it collapses (c). Such soften pool collapses result in an uneven facet floor of the WAAM build-up (d). (Photographs (b) and (d) are taken from Shah A, Aliyev R, Zeidler H, Krinke S. Journal of Manufacturing and Supplies Processing, 2023)

Soften pool parameters (corresponding to space, orientation, width, size, eccentricity, and many others.) can be utilized in real-time to create a closed-loop PID suggestions management that may make sure the thermal stability of the WAAM course of, making certain that the required cooling charges are achieved to succeed in the required microstructures, significantly when achieved together with the temperature measurements from the Xiris XIR-1800 thermal digicam. Temperature measurements can enhance the closed-loop management by controlling the interlayer temperature: as a substitute of ready for a preset time between the layers, the digicam can measure temperature of every deposited layer and the following move will be began as soon as the interlayer temperature reaches the mandatory worth.

Soften pool segmentation can be utilized in WAAM processes to ensure that materials overflow shouldn’t be occurring by checking that the weld pool dimension is at all times inside management limits regardless of warmth accumulation. Protecting the warmth accumulation inside limits will help keep away from soften pool collapses that improve the machining allowance.

Utilized collectively, temperature measurement and cooling price monitoring offered by Xiris’ XIR-1800 thermal digicam and the Meltpool AI device can provide nice management over WAAM processes.

Conclusion

Adaptive Closed-Loop Management performs a major function in addressing thermal stability challenges in WAAM (Wire-arc Additive Manufacturing) processes. By integrating Adaptive Closed-Loop Management, reaching splendid microstructures in a WAAM course of is feasible, enhancing thermal stability.

Using temperature measurements from thermal cameras just like the Xiris XIR-1800 can present extra Adaptive Closed Loop Management choices by monitoring interlayer temperature and enabling changes to the method in real-time. The result’s a course of that runs higher in management.

Keep updated by following us on social media or subscribe to our weblog!