Welding is also known as “industrial craftsmanship”, a time period that’s justified given the detailed course of concerned in combining metals by a fancy interplay of electrical energy, warmth, melting, mixing, and solidification. Generally, welding is finished to realize clean metallic joints which are each dependable and visually interesting. From bridges and airplanes to pipes, medical units, and past, welding stays a ubiquitous know-how in reaching outstanding outcomes throughout numerous industries. Despite the fact that welding is used to hitch among the most exactly engineered infrastructures on the earth, its strategies and practices stay variable and inconsistent. Despite the fact that large-scale welding functions have gotten increasingly automated, handbook welding nonetheless prevails in lots of functions relying on the experience and abilities of a welder. Both manner, the method will depend on weld parameters that had been validated a few years in the past.

Regardless of the variety of research performed on its strategies and practices, welding nonetheless falls wanting expectations. This shortfall is due to the shortage of datasets wanted to create a framework that may assist welding elevate to a science somewhat than only a craft. Amassing course of knowledge is the one technique to improve welding greatest practices and finally set up standardized protocols.

Understanding Weld Course of Knowledge

Welding a metallic joint includes melting a filler materials into the hole to create a structurally sound meeting. Over time, quite a few fastidiously assessed variables have been launched to the welding trade, all included to reinforce welding outcomes. These elements are variable and may change pre-weld, throughout welding, and post-weld. Course of knowledge helps in sustaining particular settings concerning the weld materials and the weld course of and may also help facilitate conducting comparisons and steady enhancements.

Owing to advances in sensor know-how, knowledge assortment has turn into extra achievable and interesting in difficult environments similar to welding the place security from environmental hazards from fumes, gases, radiation, sparks, noise, and hearth are paramount. For welding processes, there are a lot of sensors, for instance, thermal sensors or cameras to document warmth distribution within the weld; thermal cameras to detect the temperature of the soften pool and its surrounding space, Gasoline Sensors can analyze the composition of defending gasses used, voltage and present sensors can present real-time electrical knowledge of the ability provide, and velocimeters can measure the feed pace of the filler wire. All this knowledge can then be collected and analyzed to offer suggestions on most of the welding parameters.

Welding course of knowledge can have a big affect on the standard and formation of a weld. In automated processes, the sensor knowledge allows simple and fast optimization of the welding parameters offering a steadiness between elements like manufacturing pace and high quality. In orbital or different precision welding processes, detailed knowledge evaluation may also help to make sure high-quality welds with minimal probability of defects.

Apart from serving to reinforce weld high quality, weld course of knowledge may also assist to contribute to developments in welding know-how. Technicians, researchers, college students, and trade consultants can all achieve insights into weld course of data that extends past rapid manufacturing objectives.

Significance of Analyzing Welding Knowledge

Evaluation of weld course of knowledge throughout several types of welding and supplies helps in de-cyphering essential insights into the weld course of similar to how weld elements are functioning as per expectation, the necessity for change and enchancment, and what else might be achieved to reinforce high quality. All these discussions result in the thoroughness of weld-data recording and evaluation.

The numerous advantages of weld course of knowledge go past simply enhancing high quality, however may also improve:

- Security: The fixed record-keeping of weld knowledge helps to validate welding parameters to point out if a course of is adopted with greatest practices for security, similar to the utility–particular voltage and present restricts, the speed of gasoline circulate, air high quality requirements, surroundingsal elements, temperature steering, greatest utilization patterns, and differents.

- Upkeep: Weld course of knowledge data of kit calibrations and outcomes may also help in the early detection of gear malfunction by following the path of numbers and knowledge. Common and scheduled upkeep will finally outcome in extra constant welding outcomes.

- Productiveness: Weld data assortment finally leads to creating adjustments within the ongoing course of, to change and examine doable constrictions in manufacturing and manufacturing. The outcome is a fast and confirmed manner to enhance the high quality of the finish product, setting requirements and improving productiveness. It allows correct utilization of assets and time.

For particular person welding processes or small-scale manufacturing, amassing weld course of knowledge might initially appear pointless or overly troublesome. Nonetheless, contemplating the affect that knowledge assortment can have on total annual manufacturing makes it important for reaching operational effectivity and development. Advantages similar to these listed above stand true for each welding course of irrespective of the worth of the top product and scale of the method. Knowledge-driven outcomes assist in deciding on acceptable materials and following correct welding protocols and can be used for training functions to coach or educate new welders.

A extremely expert welder is troublesome to search out owing to the bodily side of the method, nonetheless, following a sample of numbers to achieve particular outcomes is relatively simple and is extra interesting to the present workforce. With advances within the fields of Synthetic Intelligence, Machine Studying, automation, and robotics, there are a lot of new alternatives to considerably advance the welding processes.

Ease of Weld Data Collection and Analysis Utilizing Xiris Imaginative and prescient Techniques

Xiris takes satisfaction in our vision techniques by producing merchandise that assist enhance the general welding course of by advanced know-how. Right here’s how:

- Excessive-High quality Imaging: Our excessive–decision, excessive–dynamic vary cameras are designed to work in harsh welding environments with smoke, warmth, and brilliant mild from an open arc welding course of. Our weld digicams can seamlessly seize the real-time welding course of. See: Xiris Weld Monitoring Cameras

- Automated Inspection System: Together with steadyly monitoring the weld with a digicam, machine imaginative and prescient processing can be utilized to extract data concerning the course of to robotically decide the continued strategy of welding. Robotically detecting sure weld defects and course of anomalies turns into doable, which when fed again to the automated welding gear can enable fast course of changes to right the difficulty. See Xiris Machine Imaginative and prescient Techniques.

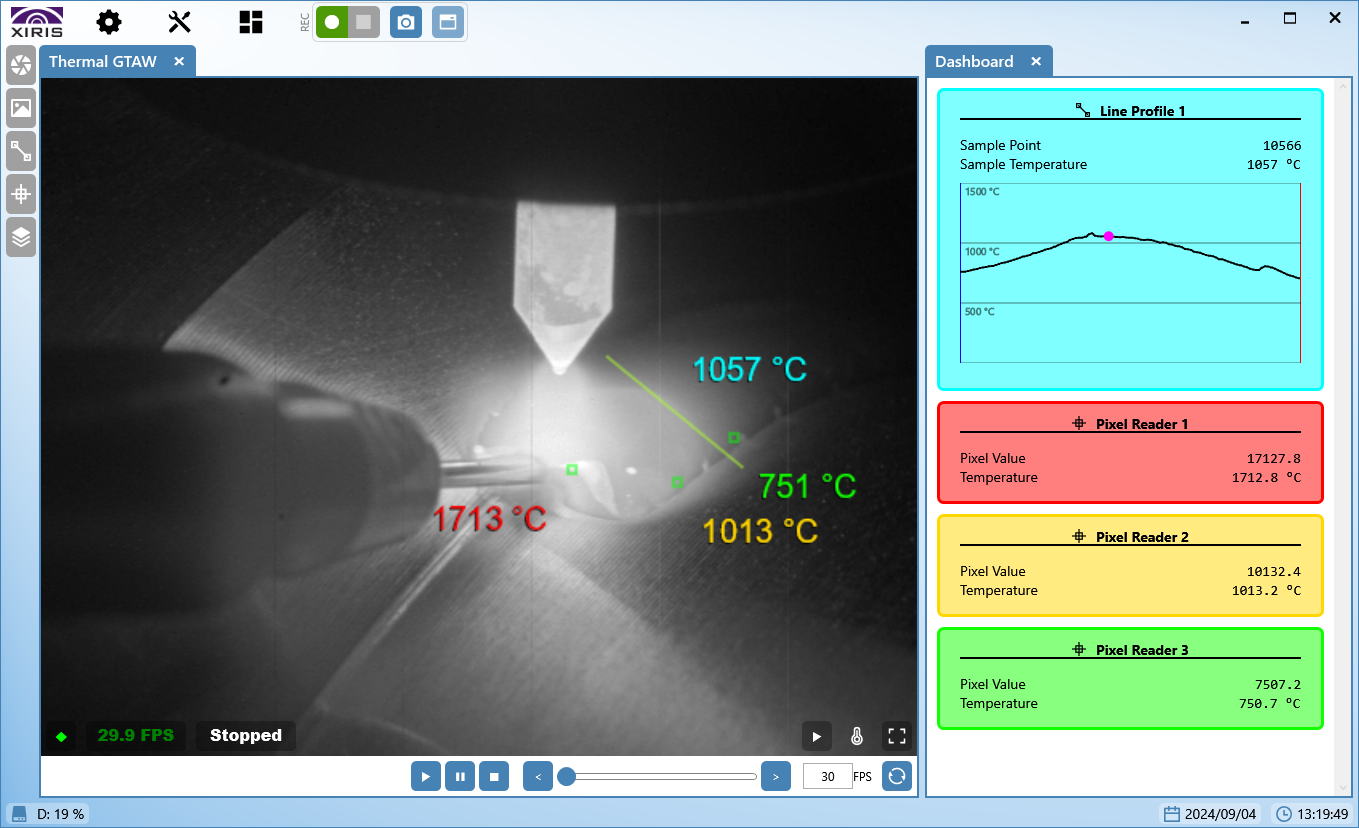

- Knowledge Assortment: Xiris’ digicam software utility, WeldStudio™, seamlessly connects to all Xiris merchandise, serving as an intuitive interface that gives digicam controls, video recording and playback, machine imaginative and prescient algorithms, and a wide selection of knowledge assortment performance. Knowledge that may be collected contains form, dimension, place, and temperature knowledge of numerous weld options similar to the soften pool, seam place, filler wire, torch tip, and weld bead to generate custom-made weld high quality metrics for any welding course of. See WeldStudio™ for more information.

- Evaluation and Reporting: Knowledge Analytics instruments similar to Statistical Course of Management (SPC) apply statistical strategies to the inspection knowledge reported from WeldStudio™ to monitor and management the traits of a welding course of. This helps be certain that the weld course of will function effectively, producing extra products that conform to specifications with much less waste.

Abstract

New developments in welding processes hinge on enhancements in high quality management pushed partially by knowledge assortment and evaluation. New sensor applied sciences have made automated knowledge assortment a a lot simpler job within the welding trade, the place handbook knowledge assortment is sort of unimaginable. For the trade to proceed to advance, high quality management is of utmost precedence, of which knowledge assortment is a vital element. Xiris offers a spread of real-time weld monitoring and inspection techniques with a confirmed document of knowledge assortment that may improve operational effectivity and help steady enhancements within the welding subject.

Keep updated by following us on social media or subscribe to our weblog!

.png?width=800&height=432&name=Fig.%203%20A%20GTAW%20Process%20with%20Various%20Machine%20Vision%20Tools%20Collecting%20Process%20Data%20(Xiris).png)