Synthetic Intelligence (AI) is altering a number of industries, and welding is not any exception.

On the earth of welding, there are quite a few components that may result in weld defects, similar to inconsistencies within the base metallic chemical composition, humidity within the welding wire, oil or paint contamination, lack of defending gasoline, incorrect welding parameters, and even incorrect torch angle.

These components can have a big affect on the standard of the weld and may end up in pricey rework and repairs.

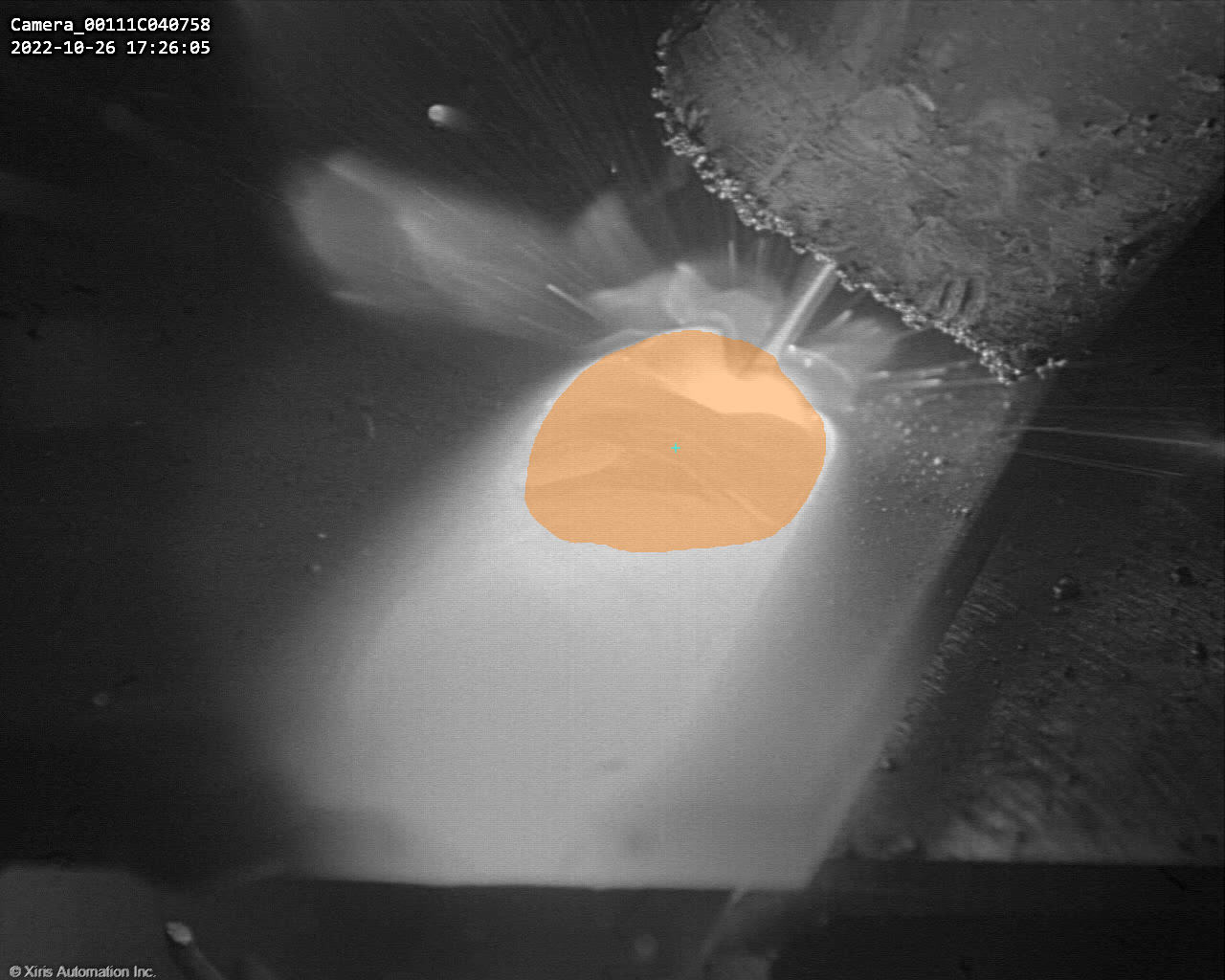

To handle these challenges, Xiris has developed a groundbreaking answer known as MeltPool AI. This progressive instrument leverages the facility of machine studying to mechanically establish and phase the weld pool from the remainder of the picture captured by a weld digicam.

By precisely distinguishing the pixels that belong to the soften pool, MeltPool AI allows exact measurements of the dimensions, form, location, and different geometrical parameters of the pool.

The soften pool is influenced by variations, and even small modifications can point out defects. Actual-time measurements from MeltPool AI assist detect and stop defects, saving time and guaranteeing weld high quality.

MeltPool AI‘s effectiveness is demonstrated within the determine beneath, the place extreme warmth enter throughout the welding of sheet metallic triggered a burn-through of the weld. The instrument detected the change within the form and dimension of the soften pool, highlighting its excessive sensitivity to even the smallest variations. This drastically enhances defect detection strategies and results in improved welding outcomes.

By leveraging machine studying algorithms, welders and inspectors can precisely measure and analyze the soften pool, enabling them to establish and deal with potential points in real-time. This know-how not solely enhances the general high quality of welding but in addition saves time and sources, resulting in improved productiveness and buyer satisfaction.

|

|

GMAW Soften Pool earlier than (left) and through (proper) a burn-through defect. The change within the soften pool geometry is immediately detected by MeltPool AI, permitting for higher Defect Detection.

Uncover the in-depth insights in our unique whitepaper: Why Soften Pool Evaluation is Necessary for Automated Welding