If you’re questioning how you can analyze a GTAW or TIG weld pool throughout welding, you’re not alone.

Almost each welder in some unspecified time in the future has needed to do some form of evaluation by measuring the dimensions, form and site of the soften pool as a approach of figuring out how nicely the GTAW course of is performing. Usually that is performed by eye via a weld helmet, however current know-how has enabled the era of such knowledge from the output of a thermal weld digicam that acquires thermal pictures of the welding course of.

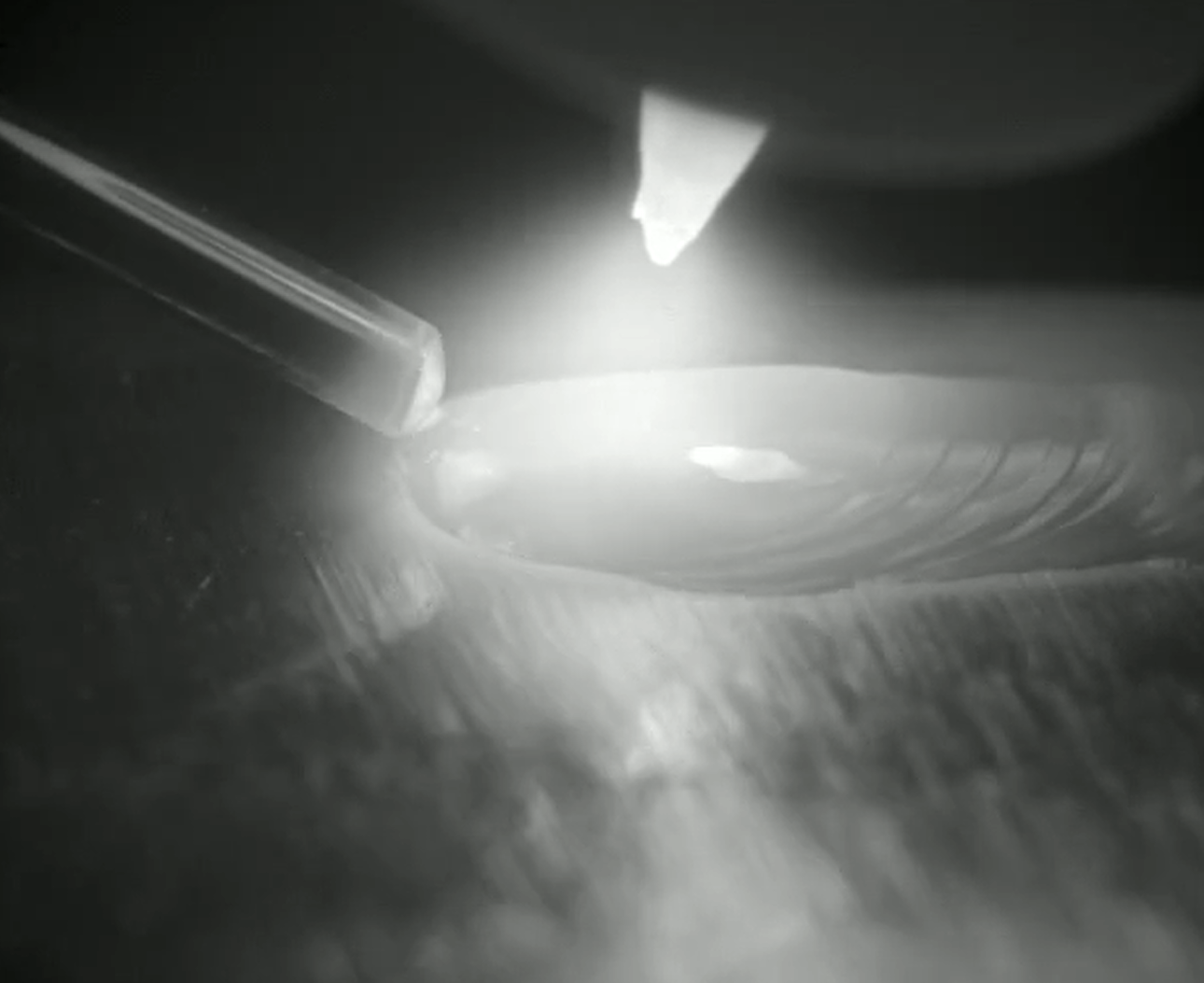

Thermal weld cameras supply temperature measurement info of the whole surroundings of the weld course of. The excessive distinction recorded video generated from a thermal weld digicam has a number of makes use of as a part of the welding high quality management course of. The recorded video itself can act as proof that the weld was accomplished appropriately and could be reviewed offline for high quality evaluation and course of evaluation. Utilizing a thermal weld digicam provides the welder a superb, excessive distinction view of the interplay of electrode, arc, dad or mum supplies, and the ensuing soften pool that decide weld bead high quality.

Whereas a typical weld digicam can seize a transparent picture of the soften pool through the welding course of, a thermal weld digicam gives an much more superior answer. By utilizing machine imaginative and prescient software program algorithms, the identical video could be analyzed to extract quantifiable knowledge that measures the soften pool’s traits. On this submit, we’ll discover how you can enhance your GTAW welds through the use of a thermal digicam to observe and analyze the soften pool, and what to think about when choosing thermal weld monitoring gear.

A thermal digicam gives two principal benefits over a typical digicam when utilizing it for GTAW weld monitoring:

(a) higher picture constancy of the soften pool and

(b) thermal knowledge that can be utilized to measure temperature at key factors in and across the soften pool.

Optimizing Orbital Welding with Thermal Cameras and Machine Imaginative and prescient

Whereas nothing replaces hands-on expertise, an apprentice welder can use a thermal digicam to document and show correct weld methods and finest practices, or to check the outcomes of excellent and dangerous welding methods. Utilizing a thermal digicam to view or document a weld is especially helpful for orbital welding procedures in a number of circumstances. It will possibly allow administration of distant welding in hazardous environments, giving the welder a real-time view of weld head exercise and soften pool traits whereas the method is monitored from a secure location.

The soften pool itself is likely one of the most essential options to be monitored in any GTAW weld course of. Whereas an excellent weld digicam can help the operator in seeing a lot of the element of the soften pool, higher picture constancy could be obtained with a thermal digicam system that is ready to present hotter objects in a picture with higher brightness and distinction than cooler objects. Because of this, the soften pool could be imaged with higher readability and sharpness, making it simpler to tell apart its boundaries from the tungsten electrode, weld arc and different parts within the weld surroundings.

This higher constancy picture permits the operator to higher see particulars of the soften pool clearly and supply a extra actual understanding of the well being of the welding course of.

The higher picture constancy that helps operators see the soften pool higher, can be helpful as an enter to machine imaginative and prescient algorithms that may extract details about the soften pool for higher selections to be made. Extra exact pictures result in extra exact knowledge that may be extracted concerning the soften pool, which usually embrace measurement, form and site knowledge.

Machine imaginative and prescient software program, equivalent to out there from Xiris’ WeldStudio software program, can analyze thermal pictures to detect temperature anomalies, monitor weld bead formation, and guarantee constant weld high quality. This data-driven method can result in improved course of management, decreased defects, and better total effectivity in welding operations.

Important Options to Search for in a Thermal Weld Digicam for Orbital Welding

The intense warmth and lightweight related to orbital welding and the constrained space of some welding operations require monitoring and recording techniques particularly designed for the job. A Excessive-quality thermal weld imaginative and prescient system ought to supply the next options:

- Excessive Dynamic Vary SWIR imaging: The very best thermal weld cameras use a mixture of Brief-Wave Infrared Imaging that captures the vary of warmth most fitted to sizzling metallic, and Excessive Dynamic Vary (HDR) imaging that may lengthen the vary of publicity via a bigger temperature vary that minimizes saturation. The result’s a thermal weld digicam that may present good element to the operator to obviously present any weld soften pool points.

- Cameras designed for the weld surroundings: The intense temperatures and radiated warmth from a weld and pre-heated substrate require thermal weld cameras that may tolerate the cruel surroundings. A water-cooled housing can shield the thermal weld digicam from the extraordinary warmth of the weld arc is required to guard the digicam in temperatures as much as 300°C / 550°F.

- Calibrated Pictures: For many versatile outcomes, the thermal weld digicam ought to be calibrated to a precision warmth supply so that each pixel can report a temperature worth that’s inside 2% of precise temperature. The digicam should be calibrated with its optics assembled to make sure the identical optics are used within the discipline as what was used for the calibration.

- Optimized Optics: The digicam’s optics ought to be optimized to function particularly within the SWIR vary of between 900-1700 nm, filtering out particular mild frequencies as a way to eradicate glare and present a transparent view of the soften pool. A wide range of lens configurations and digicam controls ought to be out there to offer totally different fields of view and dealing distances to permit operators to deal with probably the most crucial areas of the weld course of. The very best thermal weld cameras can even robotically compensate for mild depth variations between welding and non-welding modes.

- Configurability: The thermal weld digicam techniques ought to be adaptable to quite a lot of weld heads and welding functions. Correct digicam angle relative to the weld head is crucial in monitoring the soften pool high quality.

- Recording: The thermal camera system ought to talk with the welding controller to simplify the monitoring and recording of the welding course of knowledge. Programs that document the date and time present further technique of course of verification in assist of high quality management and compliance. Some thermal weld cameras (equivalent to Xiris’ XIR-1800) can take snapshots of the weld in addition to document full uncooked or processed video.

A well-designed thermal weld monitoring system has the flexibility to adapt to a variety of welding functions. As with all new know-how or system, it’s worthwhile to speculate time in establishing a check surroundings previous to utilizing the system for production-level monitoring and recording.

Testing a Thermal Weld Imaginative and prescient System

It will take some planning to place the digicam such that it’s in the very best alignment with the weld head to acquire a high-quality thermal recording of a soften pool. Trial runs with many check items are advisable because the digicam’s placement, angle, and optics are adjusted to seize the very best particulars of the soften pool. The components of the welding course of that should be monitored about their impact on the soften pool will dictate the situation and focus of a thermal weld digicam. As you fine-tune the digicam association, contemplate these essential choice components:

- Digicam Location: Steel pool’s vanguard, trailing edge, or each side.

- The place, kind, and feed charge of the wire feed can have an effect on the standard of the ultimate weld.

- The torch alignment can change the weld.

- The attainable defects (undercut, lack of fusion, porosity, burn-through, or wet-out fluidity) that may happen.

- Different components like shielding fuel interference or materials defects which can lead to weld defects.

Working with many check items provides you with an thought of the digicam’s capabilities and help in determining which digicam configuration gives the very best info for the areas of the soften pool that should be monitored. When an optimum methodology for recording a soften pool has been established, operators could use this info for quite a lot of welding functions and profit from real-time monitoring and recording.

Advantages of Studying How one can Document a Soften pool

Tlisted here are many benefits to recording a soften pool utilizing thermal weld digicam gear. Whatever the operator’s visible acuity, a purpose-built thermal weld digicam system has the know-how and functionality to offer a clearer picture of the welding course of. Digicam know-how permits the operator to deal with facets of the method that have an effect on soften pool high quality. Whether or not the aim of the thermal digicam is to document a weld for educating or studying new methods, or to observe the method for high quality assurance or operator security, weld monitoring gear can turn out to be an indispensable software for welders intent on making certain the standard and reliability of the work they undertake.

Abstract

Gasoline Tungsten Arc Welding (GTAW or TIG welding) requires meticulous consideration to element in exact, clear environments. Thermal weld cameras are important instruments that surpass normal cameras by offering detailed pictures of the soften pool. They guarantee excessive efficiency in welding operations, boosting security, high quality, and effectivity.

Improve Your Welding Expertise

See how the XIR 1800 thermal digicam can enhance your weld monitoring. Get the datasheet right here for detailed info and technical specs.

Keep updated by following us on social media or subscribe to our weblog!

.png?width=640&height=512&name=Fig.%201%20Clear%20view%20of%20a%20GTAW%20Melt%20Pool%20from%20a%20SWIR%20thermal%20camera%20(Xiris).png)

.png?width=640&height=512&name=Fig.%202%20Clear%20View%20of%20the%20GTAW%20Cooling%20Bead%20from%20a%20SWIR%20Thermal%20Camera%20(Xiris).png)

.jpg?width=1429&height=827&name=Fig.%203%20Preparing%20to%20Test%20a%20Thermal%20Camera%20(Xiris).jpg)

.png?width=1290&height=1053&name=Fig%204.%20An%20HDR%20View%20of%20the%20Melt%20Pool%20and%20Torch%20Tip%20in%20a%20GTAW%20Process%20(Xiris).png)