Warehouse operations that run like clockwork. Completely stocked, tracked, and delivered stock, and clients who can’t cease raving about your effectivity and supply occasions—that’s the final purpose! Can IoT in warehouse administration assist attain this stage of effectivity? Let’s discover out!

Offering environment friendly, good, and sustainable warehouse options is feasible. All you want is the correct applied sciences. IoT is steadily revolutionizing warehouse administration by connecting gadgets, equipment, and stock. It’s serving to main companies globally drive effectivity, scale back prices, and rework operations in actual time.

Right here’s extra on how IoT options for warehouse administration sort out widespread challenges and enhance enterprise efficiency.

Construct Good WMS Options That Caters To Your Particular Warehouse Administration Challenges

What’s the IoT in Warehouse Administration?

The Web of Issues is a community of digital devices embedded with expertise. IoT permits them to attach and alternate knowledge over the web. These gadgets can acquire and share knowledge, talk with one another, and be managed remotely.

The Web of Issues (IoT) is a viable answer to enhancing effectivity in varied industries. IoT in Warehouse Administration may also help carry out a variety of duties. It may good duties from monitoring stock ranges to optimizing workflow and offering real-time insights. It may revolutionize processes utilizing primary automation to high-grade predictive evaluation.

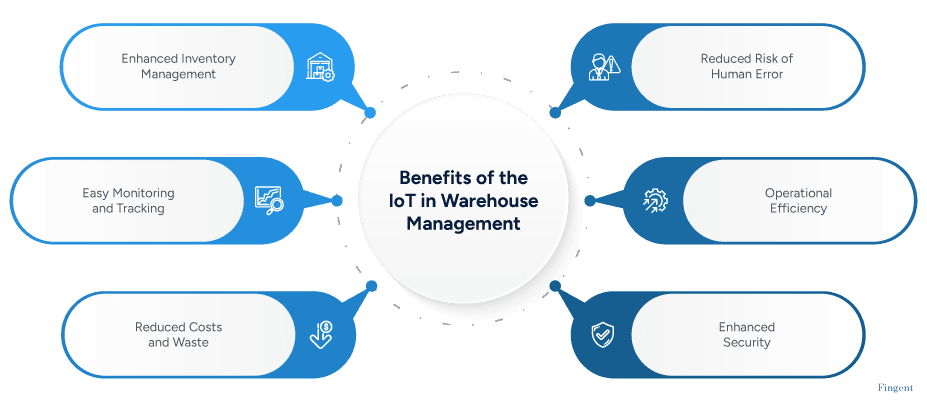

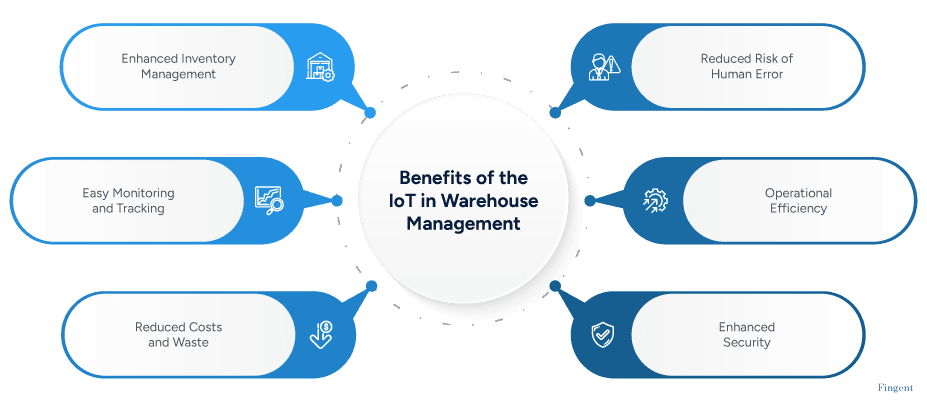

Advantages of the IoT in Warehouse Administration

The business’s progress price exhibits that companies are reaping the advantages of IoT in warehouse administration. It’s projected to develop at a CAGR of 13.1% from 2023 to 2030 and be price USD 28.79 billion by 2030!

IoT-based warehouses, also referred to as good warehouses, are making a notable distinction. The IoT has loads to supply, exhibiting advantages starting from growing effectivity to slicing prices:

1. Good Cabinets: Enhanced Stock Administration

IoTfor stock administration permits complete knowledge analytics to test stock ranges. IoT-embedded cabinets detect low stock ranges and ship fast restocking alerts. This ensures that inventory ranges are maintained effectively.

IoT offers exact monitoring of property to chop the time to find merchandise. It additionally offers correct insights into stock circulate administration. These strategic choices about inventory replenishment and useful resource allocation can rework your warehouse.

2. All Eyes on Deck: Monitoring and Monitoring

With Bluetooth connectivity, IoT can supply real-time monitoring and operation monitoring. IoT sensors built-in inside stock articles present real-time updates to warehouse managers. They observe product standing, actions, and site. It additionally offers real-time knowledge evaluation and clever insights to optimize processes additional.

IoT-based safety cameras and sensors can oversee stock cabinets and storage areas. This ensures well timed intervention and reduces the chance of stockouts or overstock. Actual-time visibility can save assets, scale back waste, and forestall spoilage.

3. Waste Not Need Not: Decreased Prices and Waste.

IoT-enabled predictive upkeep techniques can detect gear malfunctions and ship well timed alerts to warehouse managers about proactive repairs, mitigating dangers, and downtime. The IoT additionally enhances warehouse sustainability. With good lighting and local weather management techniques, warehouses can scale back the power they devour.

4. On Guard: Enhanced Safety

With IoT sensors, warehouse managers can oversee asset motion and environmental circumstances. This mitigates the chance of theft and accidents whereas guaranteeing product integrity. These sensors are designed to collect knowledge and ship real-time alerts, enabling swift and efficient motion.

5. Decreased Danger of Human Error: Operational Effectivity

The largest good thing about implementing IoT is the elimination of human error. This will exponentially enhance operational effectivity. Automated techniques can carry out mundane duties and decrease the possibilities of errors. Therefore, releasing workers to work on advanced elements of the warehouse.

Seamless integration of good gadgets and sensors can streamline workflow and enhance productiveness. These gadgets may also talk with one another in real-time. Automated guided autos (AGVs) and telematics scale back the necessity for guide intervention. Thus, boosting logistics processes’ velocity and accuracy.

Elevate Your Warehouse Administration Effectivity With New-age Applied sciences

Widespread Challenges of Implementing IoT in Warehouse Administration and Methods to Overcome Them

IoT in warehouse administration is a strong instrument that will probably be invaluable, there’s little question about that. What do you do to make sure that this instrument works for you? Step one is to acknowledge and overcome the challenges that include IoT in warehouse administration.

1. Knowledge Integration and Administration

Problem: Most organizations have various knowledge streams. Integrating these databases with none issues may be difficult.

Answer: A complete knowledge administration platform can resolve this downside. The platform can unify and normalize knowledge for evaluation. Make sure that clear knowledge administration insurance policies are laid out to evade safety dangers.

2. Legacy System Integration

Problem: That is the commonest problem amongst varied industries implementing IoT. Many companies have a legacy system that doesn’t help IoT in warehouse administration, additional complicating the mixing course of.

Answer: An efficient technique to mitigate this challenge is to make use of APIs and middleware options. They are going to present seamless knowledge alternate between IoT gadgets and legacy techniques.

3. Interoperability

Problem: Shopping for gadgets from totally different distributors can create issues, and seamless communication between these gadgets may be difficult.

Answer: Adhere to open requirements and protocols when adopting an IoT answer. Conduct thorough testing earlier than deployment to establish and handle interoperability points.

4. Value Issues

Problem: Though IoT may also help you get monetary savings in the long term, its preliminary implementation may be costly. Ongoing upkeep of sensor networks, gadgets, and infrastructure can be a value.

Answer: One of the simplest ways to handle this problem is to brace for influence. Earlier than implementation, conduct a radical cost-benefit evaluation to notice potential ROI. Flick thru varied rollouts or cloud-based options to handle prices successfully.

5. Knowledge Safety

Problem: Most enterprise house owners are more and more involved concerning the safety of their knowledge integrity. Trusting a brand new answer primarily based on the Web may be daunting, particularly relating to delicate stock and operations info.

Answer: Conduct a complete background test in your service supplier earlier than using them. As soon as the answer has been deployed, common threat assessments will probably be performed. Worker coaching in cybersecurity can be necessary. Your cybersecurity measures should embrace encryption and common patching.

6. Change Administration

Problem: Change is inevitable, however that doesn’t exempt it from being condemned by many. Profitable IoT implementation would require full help from the warehouse employees. This may be difficult, as some workers will not be tech-savvy.

Answer: Training is essential. One of the simplest ways to make sure a profitable implementation is thru open communication. Specific the advantages of IoT options for warehouse administration and spotlight how they may improve productiveness and safety. Present ample coaching to all workers in IoT expertise, software program, and processes. Start with small-scale pilot tasks earlier than implementing full-scale rollouts.

How Does Amazon Use IoT in Warehouse Administration?

Unsurprisingly, the world’s largest retail enterprise makes use of IoT in its warehouse administration system. Amazon makes use of sensors, and it’s commonplace to see robots handle duties like packing, stocking, and monitoring. It has used automated guided autos to move merchandise inside the warehouse for over a decade. Listed below are another methods Amazon makes use of IoT in its warehouse:

- Robots: Amazon makes use of 100,000 robots to maneuver and group inventory, taking cabinets with objects to the selecting and packing zone after which transferring them to the storage space. This helps to create efficiencies so as achievement and eradicate the bodily rigors of an in any other case bodily demanding job.

- RFID tags: These tags are hooked up to merchandise. Radio waves talk knowledge concerning the product to a central system. The information contains details about the asset’s location, kind, and amount. This enables warehouse managers to trace the asset with out counting on guide enter from employees.

- Linked wristbands: Amazon is contemplating utilizing linked wristbands on an entire new stage. Ultrasonic monitoring can detect a employee’s location. A haptic suggestions system takes it a step additional. Vibrations will nudge the employee’s hand in the correct path. Think about the discount in response time this might imply!

Some Often Requested Questions Across the Use of IoT in Warehouse Effectivity

1. How does the IoT rework warehouse administration?

IoT in warehouse administration can improve operational effectivity. It offers seamless integration of good gadgets and sensors, which streamlines workflow. Thus, it enhances total productiveness and reduces the chance of human error.

2. What IoT sensors can be utilized within the warehouse?

The IoT sensors which can be normally utilized in warehouses are:

- Sensors to Find and observe merchandise

- Visitors mild techniques to cut back clashes and injury

- Dock and door movement screens

- Sensors to stop nook collisions

- Sensors to ship alerts when inventory is low

3. How can IoT enhance the logistics course of?

IoT in warehouse administration can enhance logistics processes by way of real-time monitoring. It permits a dynamic real-time monitoring of shipments and property, enhancing route administration and supply accuracy.

4. What are the advantages of IoT in logistics and warehouse administration?

The advantages of implementing the IoT in warehouse administration are multifaceted. They vary from a streamlined circulate of products and lowered errors to elevated visibility in stock ranges.

5. What industries profit most from IoT in warehouse administration?

Retail, e-commerce, manufacturing, logistics, prescribed drugs, and the meals and beverage industries profit probably the most from IoT in warehouse administration. These industries are likely to have sophisticated provide chains and enormous inventories. Therefore, IoT can present the best effectivity, accuracy, and price financial savings benefit.

Scale back Labor Prices With Warehouse Automation

How Can Fingent Assist Convey Warehouse Effectivity to New-Age Know-how?

Implementing the IoT in warehouse administration requires a deep data of the expertise and an innate sense of the way it can work for your enterprise. Fingent is a service supplier with shoppers the world over. We provide huge and intensive expertise in delivering extremely intuitive functions and options. Our specialists can add immense worth to your technique and make seamless deployments. We will make your processes environment friendly, reduce extreme prices, and unlock hidden potential.

We perceive the necessity to implement the most recent developments in warehouse administration techniques. A living proof is the web-based answer that we just lately supplied for considered one of our shoppers in Australia. The answer helped the shopper to trace, management, and effectively handle deliveries. This resulted in

- 43% enhance in buyer base

- 50% discount of inside workload.

Fingent has helped main companies create product ordering techniques, e-commerce functions, and extra to allow optimized operations. We assist organizations undertake cutting-edge expertise whereas progressively changing legacy techniques, enabling them a aggressive edge!

Take buyer satisfaction to a different stage with us! Contact us now!