Regardless of over a decade of speak about “industrial digital transformation”, it’s solely now we’re observing a tipping level. In keeping with the VDC Analysis report Securing OT with Goal-built Options, solely 7.6% of surveyed industrial organizations contemplate themselves totally digital, however inside two years 63.6% count on to be so. This shift is pushed by two most important components: financial strain pushing firms to radically enhance effectivity, and the rising accessibility of applied sciences resembling the economic web of issues (IIoT) and edge computing.

Digitalization helps industrial enterprises enhance each their effectivity and security. Most organizations have already applied asset, upkeep, and supply-chain administration techniques that cut back downtime and working prices. Extra superior applied sciences like digital twins and predictive analytics considerably enhance processes, enhance manufacturing, and minimize waste of supplies and sources. Integrating information from IT techniques and ICS allows real-time decision-making primarily based on up-to-date data.

However with integration comes vulnerability: techniques that have been as soon as remoted or not digital in any respect turn out to be prone to IT failures and direct cyberattacks. Assaults on OT techniques can result in elevated defect charges, failure of advanced gear, disruption of downstream manufacturing processes, and even catastrophic occasions that threaten employee security. Even temporary outages can have severe enterprise penalties and injury an organization’s fame.

Main obstacles to industrial digitalization

In keeping with the surveyed firms, cybersecurity issues have turn out to be the principle barrier to industrial digital transformation. Practically 40% of the businesses surveyed within the VDC report say they should resolve this subject to maneuver ahead. Different prime challenges embody funds constraints and outdated gear that’s too advanced and costly to improve for digital tasks.

In relation to safety particularly, the highest points embody an absence of sources for securing ICS gear, insufficient safety measures in current infrastructure, and difficulties with regulatory compliance

The price of an incident

When justifying cybersecurity budgets and planning for additional growth, consultants unanimously advocate a risk-based method tailor-made to the group’s profile, its danger urge for food, trade specifics, and different components. The VDC Analysis report gives vital information for this, documenting the character and monetary affect of safety incidents in industrial organizations from 2023 to 2024. For instance, 25% of surveyed firms that skilled safety incidents with measurable monetary penalties reported damages exceeding $5 million.

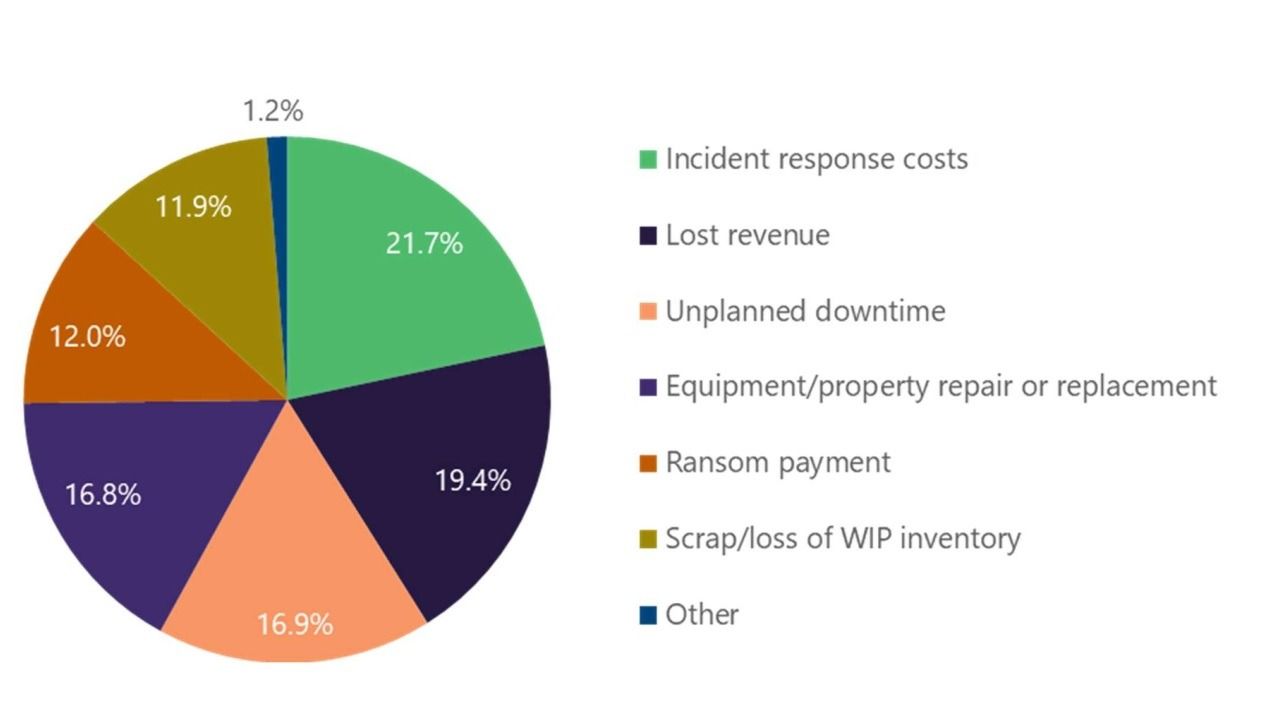

These prices embody response efforts, direct income loss, and industrial-company-specific bills like gear repairs and losses of uncooked materials or semi-finished items. One of many top-three prices is unplanned downtime — a vital metric that industrial digitalization particularly goals to scale back. Most incidents resulted in downtime lasting 4–12 hours or 12–24 hours (with every vary representing a few third of instances).

The price breakdown is visualized under:

The challenges of defending ICS

Regardless of the acknowledged want for ICS cybersecurity and regulatory necessities, implementation stays troublesome. Nearly each surveyed group faces the next challenges:

- Restricted visibility into OT networks attributable to quite a few specialised communication protocols and incompatibility with customary IT monitoring instruments

- A scarcity of specialists expert in working with proprietary techniques and industrial protocols

- Inadequate community segmentation and the shortcoming to isolate susceptible gear attributable to enterprise wants; emergence of many new connections between IT and OT infrastructure

- A rising variety of IIoT units with insecure configurations and susceptible firmware (producers typically neglect safety)

- Outdated software program and irregular patch releases

- Delayed patch set up as a result of want for intensive testing and coordination with operations groups concerning the set up window

- Lack of detailed incident response plans that have in mind vital occasions in OT networks

A few of these points can’t be solved on the firm stage alone, however investing in specialised and built-in cybersecurity options can considerably mitigate the dangers.

Specialised safety

Whereas ICS safety tasks are inherently advanced, deploying specialised options purpose-built for OT/IT environments can enhance effectivity and cut back dangers. Key instruments embody asset and community visitors monitoring options (resembling Kaspersky Industrial Cybersecurity for Networks) and endpoint safety options (resembling Kaspersky Industrial Cybersecurity for Nodes). Organizations with mature cybersecurity applications use these as a part of a defense-in-depth technique — a multilayered safety method.

These options have options designed particularly for industrial networks, resembling avoiding disruption of vital processes and communication, and working with restricted reminiscence and processing energy. This helps keep away from meltdowns just like the infamous CrowdStrike incident, the place a careless safety replace disabled protected techniques.

Within the close to future, applied sciences like SD-WAN after which SASE will play an even bigger function by embedding safety deeply into community structure whereas making certain resilience. Finally, the gold customary is a secure-by-design structure, which needs to be constructed into sensible industrial gear by producers on the outset.

Safety implementation is a severe venture — not only for the cybersecurity crew but in addition for engineers and plant operators. Because of this, venture approval and rollout are sometimes delayed. To scale back the burden on everybody concerned, and likewise pace up the deployment of safety, firms ought to keep away from a fragmented hodge-podge of safety instruments, and as a substitute use complete options from a single vendor. This simplifies each deployment and ongoing administration by higher integration. In keeping with VDC’s survey, round 60% of organizations favor getting all their safety options from one supplier.

How safety saves cash

Regardless of the challenges, firms adopting specialised ICS safety options are already seeing clear financial advantages.

The VDC report exhibits that from 2023 to 2024, the variety of incidents decreased in firms that deployed community and system monitoring instruments. On common, incident charges dropped from 2.7 to 2.2 per 12 months. Organizations utilizing customary endpoint safety introduced incidents down from 2.1 to 1.6. In distinction, industrial firms neglecting IT and OT safety skilled a median of three.8 incidents — about twice as many as their better-protected rivals.

You’ll be able to discover extra about typical industrial digitalization tasks, cyber incident injury estimates, and complete safety suggestions within the full VDC report.