Integrating a Weld Digital camera to Laser Welding Processes

Excessive powered industrial lasers have been integrated in a wide range of metallic fabrication processes, mostly for welding and reducing functions, the place the excessive energy of the laser permits for speedy processing speeds.

As fabricators have adopted industrial lasers all through their store ground, it has turn out to be painfully apparent to the fabricators that the fabric being processed by lasers needed to be ready and aligned otherwise than conventional processes. As a result of a laser beam is so small, exact match up and alignment of the fabric being processed is required to make sure the laser course of is viable.

Cautious monitoring of the match up and alignment is required to make sure an excellent welding course of. Due to the protection problems with being round a laser mild, the one sensible approach to monitor how the fabric has been ready and aligned to the laser head was to make use of a digital camera that was built-in to the laser beam supply system.

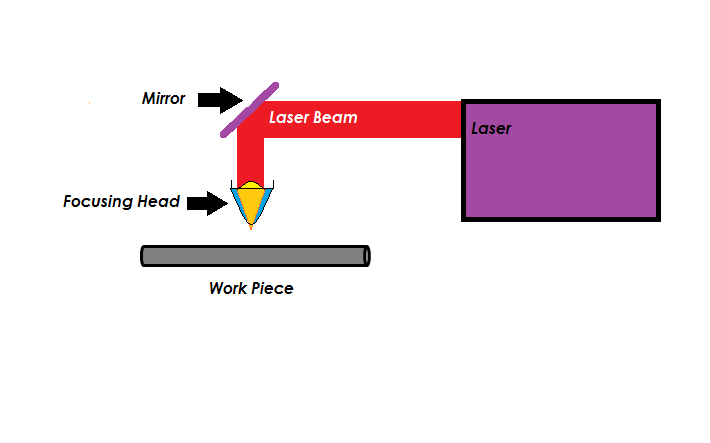

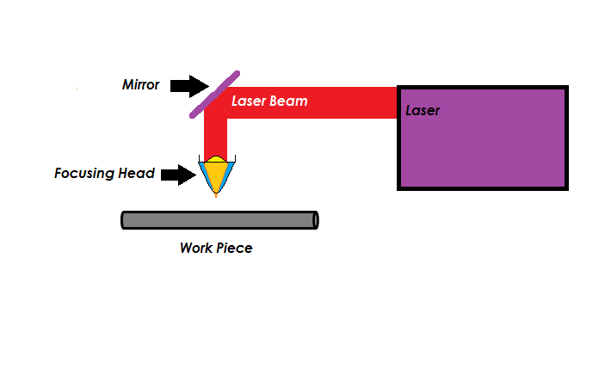

The laser beam supply system

The laser beam on most reducing and welding techniques is delivered to the work piece utilizing a sequence of optical elements akin to lenses, filters and mirrors.

Collectively the meeting is named the “laser beam supply system” and will be advanced in form and dimension to go well with the appliance, because the laser could must be bent to be as compact and practical as doable.

Most laser beam supply techniques have a digital camera port built-in into the meeting to permit a digital camera to view down the identical optical path as that travelled by the laser beam.

By including a digital camera to the beam supply system, the operator can monitor the workpiece materials to make sure it was correctly ready and aligned previous to powering up the laser.

|

A Simplified Laser Bead Supply System

The Downside

As soon as the concept of placing a digital camera on the laser system has been accepted, there may be typically frustration with the truth that the cameras mostly used turn out to be ineffective as soon as the laser is turned on.

As a result of the laser generates huge quantities of centered mild that partially bounces as much as the digital camera or creates very brilliant keyholes and weld puddles as soon as it hits the work piece, the ensuing picture is simply too brilliant for traditional cameras to see any element within the brightest sections of the picture.

As a typical digital camera can see about 48-60 dB of vary of brightness, it’ll merely saturate the place the picture will get too brilliant, leading to a white blob on the display screen.

The answer applied by many fabricators and tools builders? Flip off the digital camera when the laser is powered.

A Higher Answer

Nevertheless, a greater resolution does exist. A excessive dynamic vary weld digital camera can be utilized instead of a typical digital camera to adapt to the laser course of.

A very good weld digital camera can see greater than 140 dB of vary of brightness, or a ratio in extra of 10,000,000:1 of the brightest to darkest pixels in a picture.

This enables for element within the brightest space of the picture of a laser weld or reduce to be seen with out saturation whereas nonetheless seeing element of the background across the weld, together with the weld pool or seam.

By implementing a weld digital camera to see the laser course of, an operator can see what’s going on with their laser welding course of as soon as the laser energy is on, guaranteeing that the laser beam is functioning accurately: that the beam is concentrated correctly, that the keyhole is of the proper form (spherical vs. oval), dimension and placement (relative to the weld seam), and that the weld pool is symmetric on both facet of the weld seam and sized accurately.

|

Picture from a Excessive Dynamic Vary Digital camera of a 3000 W Laser |

For extra data on how Xiris Weld Cameras may help monitor your weld processes, go to Xiris.com

Signal as much as obtain our Weld Video of the Month

Keep updated by following us on social media or subscribe to our weblog!