Are you contemplating a much-needed improve to your welding gear? When you’re at present counting on an older or underperforming welding digital camera just like the Toshiba IK-M44H lipstick digital camera or different analog cameras, it is perhaps time to discover newer alternate options. One such possibility is the Xiris XVC-310 HDR coloration weld digital camera, designed to seamlessly exchange your outdated Analog mannequin and thought of the perfect GTAW welding digital camera when it comes to efficiency and options.

The XVC-310 HDR digital camera has a 17mm diameter housing, permitting it to slot in the identical house because the older Toshiba cameras with minimal mechanical modifications required for a simple substitute. However what units the Xiris XVC-310 aside from any analog welding digital camera? Let’s delve into the important thing variations between these two micro cameras and discover why the XVC-310 is the popular alternative for quality-focused welding functions.

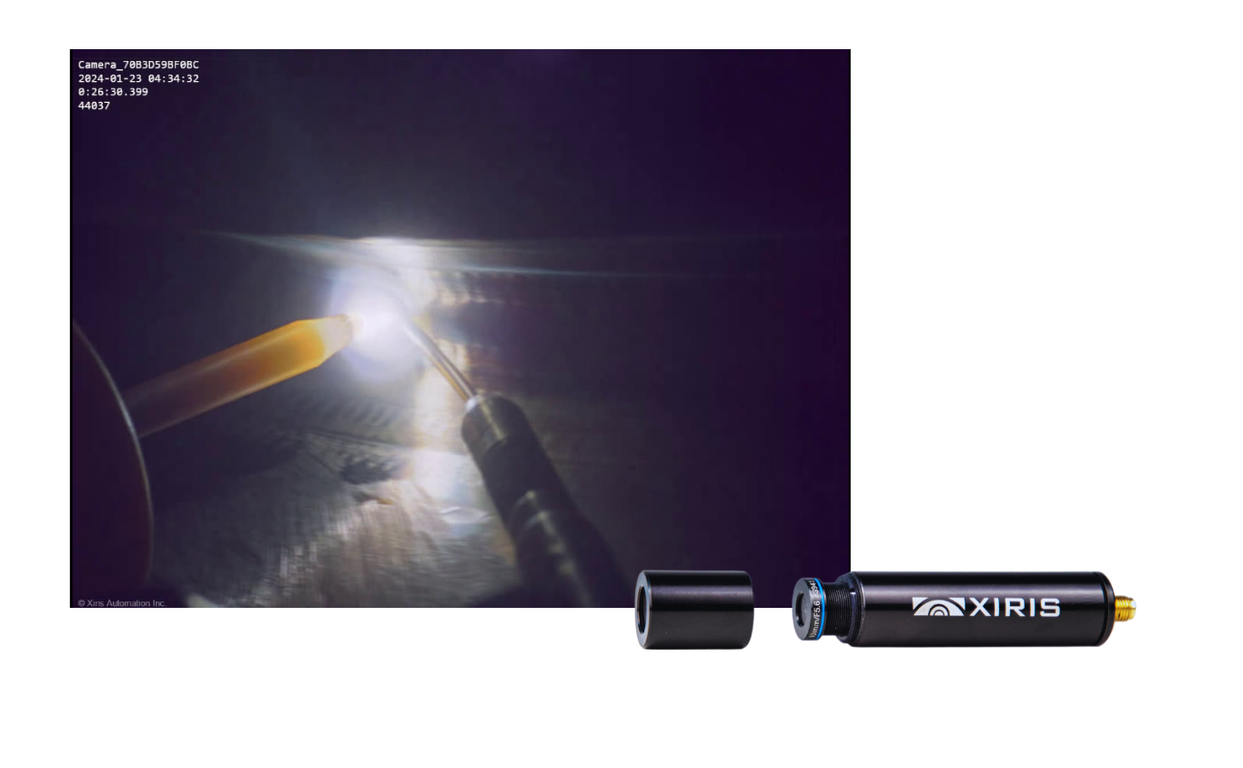

- Excessive Dynamic Vary (HDR) Imaging: Clearly captures each the brilliant weld arc and the darker surrounding space.

- Rugged, IP65-Rated Housing: Appropriate for harsh manufacturing environments.

- Superior Software program Integration: Appropriate with Xiris’ WeldStudio software program for superior picture processing and distant monitoring.

- Superior Picture High quality: Supplies clear pictures of the soften pool and welding space traits throughout each welding and non-welding inspections.

- Straightforward Alternative: Direct drop-in substitute for the Toshiba digital camera, requiring minimal mechanical design modifications.

These options make the XVC-310 the best substitute for older lipstick fashion welding cameras just like the Toshiba IK-M44H, which had been closely utilized in orbital welding or slim groove welding functions.

The simple improve path means that you can profit from the newest digital camera expertise with minimal disruption to your current welding setup.

Variations between analog choices just like the Toshiba IK-M44H and the Xiris XVC-310 Welding Cameras.

1. Imaging Capabilities:

The Xiris XVC-310 options HDR imaging, permitting it to seize each shiny and darkish areas of the weld. The Toshiba IK-M44H lacks this superior HDR function.

2. Dimension and Mounting:

The Xiris XVC-310 is 17mm in diameter, the identical measurement because the Toshiba IK-M44H, making it a direct substitute with minimal mechanical modifications required. This ensures a simple and quick improve course of.

3. Software program Integration:

The Xiris XVC-310 integrates with WeldStudio software program for superior picture processing and distant monitoring capabilities, in contrast to the Toshiba digital camera.

4. Ruggedness:

The Xiris XVC-310 has a ruggedized, IP65-rated housing appropriate for harsh manufacturing environments.

5. All Digital:

The Xiris XVC-310 is a totally digital digital camera outputting digital video information through GigE. This permits video data to be transmitted as much as 100 meters away from the digital camera with out degradation. The video data could be displayed, recorded, and performed again for on- or offline assessment.

6. UV Resilience:

Analog cameras just like the Toshiba IK-M44H are liable to growing “blind spots” that develop over time because of extended publicity to UV rays, which burn the sensor over time. This degradation is inevitable and compromises the digital camera’s capability to seize clear and correct pictures.

7. Information Processing Benefit:

As an analog digital camera, the IK-M44H lacks the superior picture processing capabilities of contemporary digital cameras, leading to slower information processing and fewer efficient real-time monitoring. Fashionable digital cameras supply superior picture processing, enabling faster and extra correct real-time evaluation and changes throughout the welding course of.

Conclusion

The restrictions of analog cameras in decision, dynamic vary, sturdiness, and information processing make them much less appropriate for present welding functions. Transitioning to superior digital programs just like the Xiris XVC-310, with larger decision, higher dynamic vary, enhanced sturdiness, and superior information processing capabilities, is important for reaching the inspection and monitoring objectives required in as we speak’s welding environments.

In abstract, programs just like the XVC-310 superior digital digital camera are a mandatory improve to extend the productiveness of your welding system.

Keep updated by following us on social media or subscribe to our weblog!